UK Rubber Extrusion Manufacturer

Our extensive knowledge of both the design and manufacture of rubber extrusions, means we can produce and supply standard or custom-made rubber extrusion profiles for most applications, whether you need small or large volumes.

We can offer our customers various sizes and quantities of rubber extrusions to suit specific needs and all of our extrusion profiles and materials are manufactured to British, European or International standards or to exact customer specifications.

Extruded rubber products can be lightweight, flexible, durable and long-lasting. The continuous rubber extrusion process can produce parts in a variety of lengths and shapes relatively cost-effectively and with very little material waste.

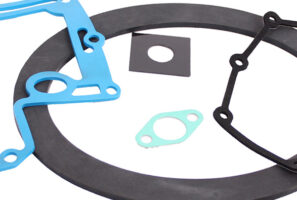

Common extruded rubber products are rubber bushings, rubber cords, door seals, trims, tubes, hoses, pipes, gaskets, O-rings, and weatherstrips. Our rubber extrusions are supplied to a wide range of industries including Construction, Oil & Gas, Transport and Agriculture. In the Transport industry we regularly supply D section extrusions for protective sheeting and seals for vehicles.

Our History and Expertise

Since 1973 we have developed significant technical expertise in the manufacture of rubber extrusions in the UK. Our expert team have accumulated many years’ experience in creating rubber profiles and can advise on any issues or queries you may have.

To maintain a quality product and service we put quality at the heart of our processes. Our quality management system is therefore certified to ISO9001.

The Rubber Extrusion Process

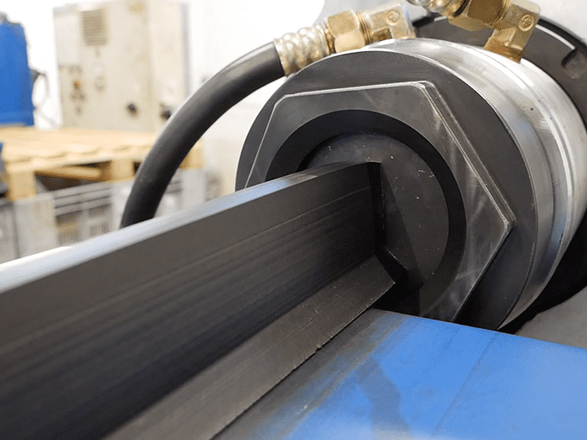

The term rubber extrusion is defined as producing a product with a consistent cross-sectional shape by pushing uncured rubber material through a mould die. There are two main types of extruder used to push the rubber through the die, these are screw extruders and ram extruders and the choice of which to use will generally depend on the length and quantity of the extrusion profile required.

The vulcanisation process takes place once the profile has been extruded generally using microwaves, steam autoclaves, hot baths or hot air. The rubber profiles are then packaged and made ready to ship to our customer.

The rubber extrusion process is an efficient and economical manufacturing process, as it produces a low volume of waste material.

Rubber extruded rubber parts are lightweight, extremely durable, flexible and have a long-life span. They are extremely resistant to chemicals, heat, cold, aging, fatigue, friction, abrasion and other wear and tear, so are ideal for a wide range of applications.

Once an extrusion has been moulded it will go through a finishing and inspection process to ensure the part is dimensionally accurate and free from any surface defects, is fit for purpose and meets our quality standards and the customer’s specifications.

The Products Produced

Always striving to meet customer requirements, the most common rubber extrusion profiles we supply include:

- 'D' Sections

- 'E' Sections

- 'L' Sections

- 'P' Sections

- 'U' Channels

- Box Sections

- Trapeziums

- Lip Seals

- Rubber Tubes

- Rubber Cords

- Rubber Piping

- Rubber Door Seals

Extrusion Materials

Typically our rubber extrusions are manufactured from EPDM or silicon but other rubber materials can be specified, such as Nitrile or Neoprene. EPDM is available as either a dense or sponge.

We can also manufacture special extrusion profiles in the following material grades:

- High and Low Temperature

- WRAS Approved

- Flame Retardant

- Anti-Static

- FDA/Non-Toxic

We can produce coloured rubber profiles in the UK to suit and Shore hardness can be specified as required.

Find out more about our other Capabilities

Companies We've Worked With

Industries We Work In

We create bespoke and custom rubber mouldings for use in specific industry applications. Our rubber products and mouldings are trusted by many of the world’s leading companies for use in some of the harshest environments, across a range of different industries:

Rubber Extrusion FAQs

-

What is the current manufacturing process?

The term rubber extrusion is defined as producing a product with a consistent cross-sectional shape by pushing uncured rubber material through a mould die. The vulcanisation process takes place once the profile has been extruded generally using microwaves, steam autoclaves, hot baths or hot air. The rubber profiles are then packaged and made ready to ship to our customer.

-

Are there different types of rubber extrusion products?

Common extruded rubber products are rubber bushings, rubber cords, door seals, trims, tubes, hoses, pipes, gaskets, O-rings, and weatherstrips.

-

Can you work to custom specifications?

Absolutely. We work with you to meet your requirements whatever shape or size rubber extrusion product you require.

-

What is the most common material used for rubber extrusions?

The most common material for rubber extrusion is EPDM which is a synthetic rubber compound with excellent properties suitable for most extrusion profile applications.

-

What are the most common Extrusion profiles?

- ‘D’ Sections

- ‘E’ Sections

- ‘L’ Sections

- ‘P’ Sections

- ‘U’ Channels

- Box Sections

- Trapeziums

- Lip Seals

- Rubber Tubes

- Rubber Cords

- Rubber Piping

- Rubber Door Seals

-

What's the typical manufacturing time frame?

A typical product will take about 4 working weeks to complete from start to finish.

-

Do you cover all industries?

Yes – we can manufacture extrusions for all industries and already supply to a wide cross section of industries.