Custom Agricultural Rubber Component Manufacturer & Supplier

Clifton Rubber is the industry leading manufacturer of rubber and polyurethane agricultural products supplying OEMs and tier 1 suppliers across the UK and European agricultural sector.

Our products are used in a wide range of plant and equipment predominantly in the root crop sector. Technology in use with Clifton products include stone separators, planters, cultivators, harvesters and handling equipment such as hoppers, graders and fillers.

In addition to our universal products we are able to work with our customers to manufacture bespoke products for new or existing applications.

The agricultural industry uses rubber and polyurethane components due to the unique properties of the materials which make them ideal for use in challenging environments. These unique properties contribute to the performance and longevity of equipment, machinery, and infrastructure used in farming and agricultural processes.

From moulding processes and extrusion to precision engineering, discover how these components play an essential role in enhancing the agricultural process.

Custom Agricultural Rubber Component Manufacturing Services

Rubber Moulding For Agricultural Vehicles & Machinery

Rubber moulding is a commonly used manufacturing process for producing agricultural components. It allows for mass production of both simple or complex shapes as well as bespoke custom-designed parts with consistent quality. Common agricultural components produced using rubber moulding include:

- Stars and Discs for the gentle cleaning, grading, sorting and de-stoning of root crops

- Rubber rollers for baler, harvesting and handling machines

- Pintle products for washing of crops, various crop handling applications, sorting and grading.

- Conveyor belts and rollers for handling crops and materials in agricultural processes.

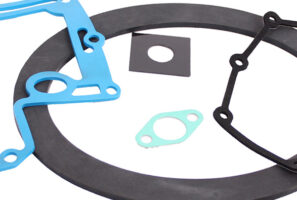

- Seals and gaskets for agricultural machinery and irrigation systems.

- Anti-vibration mounts, web drives and shoes for machinery to reduce noise and vibration.

- Wheels and tyres for agricultural equipment such as tracked tractors and harvesters.

- Web drives and drive shoes for machinery.

- Hoses and tubing for liquid and irrigation systems.

But that’s not all. At Clifton Rubber, we can create custom components tailored to specific agricultural customer needs, such as vibration isolation mounts and conveyor belts. These components enhance operational safety, increase precision, and optimise performance.

Our rubber moulded products provide excellent resistance to harsh agricultural environments, ensuring flexibility, durability and longevity for agricultural vehicles and machinery. This helps in minimising equipment downtime and maintenance costs.

Polyurethane Moulding For Agricultural Vehicles & Machinery

Polyurethane is known for its exceptional resistance to abrasion, chemicals, and UV radiation, making it ideal for demanding agricultural environments. Common agricultural components produced using polyurethane moulding include:

- Rollers for agricultural machinery such as harvesters and conveyors.

- Stars and Discs for the gentle cleaning, grading, sorting and de-stoning of root crops.

- Cleaning coils to provide extremely gentle handling and cleaning of root crops in various types of processing equipment such as graders, sorters and receiving hoppers.

- Grading spools used to accurately sort potatoes and other crops in root crop sorting and grading equipment.

- Cleaning Segments to gently separate clod, stones, haulm and loose soil from a wide range of fruit and vegetables

- Bushings and bearings for various agricultural equipment to reduce friction and wear.

- Seals and gaskets for pumps, valves, and hydraulic systems used in agriculture.

- Wear-resistant pads and liners for agricultural machinery parts.

- Anti-vibration mounts and bumpers to dampen noise and vibrations.

Polyurethane moulding has many advantages as polyurethane is a versatile material that can be customised to meet a customer’s requirements. Its advantages include durability, wear resistance, and excellent load-bearing capabilities, which all help to improve the performance, productivity and lifespan of agricultural equipment.

Rubber Covering including

- Rubber Rollers For Agricultural Machinery and Vehicles

- Rubber Wheels & Tyres For Agricultural Vehicles & Machinery

Rubber Covering (also known as rubber coating or rubber lining) provides excellent traction and grip, enabling efficient movement and operation of agricultural machinery. The rollers’ resilient and wear-resistant properties contribute to smoother processing, reducing slippage and improving productivity.

Common uses of rubber covering in agriculture include:

- Agricultural Rollers: Rubber covering is used on rollers that come in contact with agricultural materials during processing, such as feed processing rollers or harvesting equipment rollers. The rubber coating provides improved traction, prevents slippage, and reduces wear on the rollers.

- Wheels and Tyres: track tractor wheels including mid, idler, drive and front wheels for all track systems.

- Anti-Vibration Pads: Rubber-coated anti-vibration pads are used in agricultural machinery, such as tractors and harvesters, to reduce vibrations and noise. This improves operator comfort and extends the lifespan of the machinery.

- Sprayer Nozzles: Rubber coatings can be applied to sprayer nozzles to enhance wear resistance and reduce clogging, ensuring efficient application of agricultural chemicals.

- Conveyor Belts: Used to transport crops, grains, and other agricultural products. The rubber coating improves the belt’s grip and durability, ensuring efficient handling of materials.

Rubber Covering enhances the performance, durability, and safety of equipment and components. It helps to reduce maintenance costs, prevent equipment failure, and ensure a longer lifespan.

Rubber Rollers For Agricultural Vehicles & Machinery

We manufacture, cover and refurbish rubber rollers used in various agricultural applications:

- Harvesting Equipment: Rubber rollers are frequently used in harvesting equipment, such as combine harvesters. The rollers help to grip and feed the crops through the machine for processing.

- Conveyor Systems: Rubber rollers, such as transfer rollers, are integral components in conveyor systems used for transporting agricultural products like grains and fertilisers.

- Processing Machinery: Rubber rollers are used in processing machinery for crushing, grinding, and compressing agricultural products.

- Preparing Fields for Seeding and Planting: Clod rollers are utilised in machinery used for harvesting and seeding. It breaks down clods of soil, or clumps of soil that can be left behind after ploughing has taken place.

- Baling – baler rollers are used in machines used to compact and bale various materials, such as hay, straw, or other agricultural crops, into dense, manageable, and uniform packages known as bales

Root Crop Cultivation – haulm rollers are used in root crop cultivation. to remove the green foliage, known as “haulm” from the top of the crops before harvesting.

We regularly refurbish rubber rollers for machines including Claas, John Deere, Krone,and New Holland among others.

Rubber rollers help improve efficiency, productivity, and product quality. Their traction, grip, and durability make them ideal for use in various types of agricultural machinery and equipment.

Rubber Wheels and Tyres For Agricultural Vehicles & Machinery

Rubber wheels and tyres for agricultural vehicles and machinery offer crucial advantages. They provide superior traction, stability, and flotation, ensuring optimal performance in various terrains. Our rubber wheels offer excellent durability and impact resistance, which minimises damage to crops and soil compaction.

We strip and re-cover mid, idler, drive and front wheels for all agricultural track systems including: Case Quadtrac, Challenger Mobil-trac, Claas Terra Trac, John Deere Track, New Holland Smarttrax.

We re-cover your existing track tractor wheels in rubber or polyurethane and where possible offer a service exchange service so that used track wheels can be exchanged for refurbished wheels held in stock.

Rubber Extrusion For Agricultural Vehicles & Machinery

Components produced via our Rubber Extrusion process enjoy the versatility and customisation capabilities associated with this unique process. We place an emphasis on the ability to create bespoke rubber profiles, seals, and gaskets through extrusion. These components provide effective sealing, protection, and insulation, enhancing the efficiency and reliability of agricultural equipment.

Rubber extrusions are used in components that require sealing and protection. These include:

- Seals and Gaskets: to protect against liquid leakage, air, dust and noise.

- Conveyor Belts: Rubber extrusions are used to make conveyor belts for agricultural material handling. They provide grip, flexibility, and durability, enabling efficient and reliable transportation of crops and other agricultural products.

- Tubing and Hosing: for fertilisers, liquid and irrigation.

- Vibration Dampening: used in agricultural machinery to reduce vibrations and noise.

- Spray Nozzle gaskets: to prevent leakage.

Rubber extrusions are versatile and can be used in a wide range of agricultural applications. They protect, seal and enhance the performance of a wide range of agricultural equipment.

Rubber Sheet Conversion For Agricultural Vehicles & Machinery

Rubber sheet conversion for agricultural vehicles and machinery provides a range of applications. We provide the ability to convert rubber sheets into liners, mats, and protective covers. These versatile products offer benefits such as impact resistance, noise reduction, and surface protection, contributing to the durability and performance of agricultural vehicles and machinery.

- Gaskets and Seals: Rubber sheeting is cut and shaped into gaskets and seals used in various agricultural equipment and machinery.

- Vibration Damping Pads: Rubber sheeting is employed as vibration damping pads for machinery and equipment, reducing vibrations and noise levels during operation.

- Lining: Rubber sheeting is used as a lining material for ponds and other water features on farms

Precision Engineering For Agricultural Vehicles & Machinery

The importance of precision-engineered components in agriculture, such as seals, bearings, and bushings is key in an industry that relies on efficient production.

Our components ensure proper alignment, reduce friction, and enhance overall operational efficiency in agricultural applications.

Our precision engineering division maintains a comprehensive engineering capability providing in-house and sub-contract toolmaking, machining and fabrication services.

Our highly skilled engineering team have over 50 years’ experience in the machining of precision engineered components, from complex mould tools and single one-off bespoke items to high volume production runs of CNC machined parts.

Our design team can help you solve complex problems and will work with agricultural clients to find solutions for your component requirements.