Rubber and Polyurethane Components Used For The Water and Sewage Industry

Clifton Rubber is a specialist rubber & polyurethane manufacturer supplying products to a wide range of industries including Water and Sewage. Our products are used for various applications to ensure the efficient and reliable operation of water and sewage plants and systems.

Clifton Rubber Capabilities By Industry: Water and Sewage

Rubber Moulding For The Water and Sewage Industry

Rubber Moulding enables the creation of custom-designed rubber components that withstand harsh outdoor environments, including corrosion, extreme temperatures, flooding, and high-pressure conditions – all common in the water and sewage industry.

Rubber components play a crucial role in sealing and insulating, ensuring watertight connections and preventing leaks in pumps and pipelines.

Clifton Rubber’s products provide cost-effective solutions, allowing mass production of identical components, and reducing downtime and maintenance expenses.

Our flexibility in design and production allows customers to adapt to evolving requirements, enhancing overall productivity and reliability. Our rubber components are WRAS approved and can be custom made and ready for you.

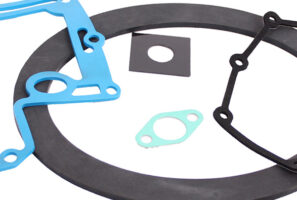

Typical rubber moulded components used in the water and sewage industry include:

- Gaskets and Seals: to create watertight connections between pipes, valves, and other components.

- Expansion Joints: employed to absorb movements and vibrations in pipelines, ultimately helping to prevent damage to the piping system.

- Hoses and Couplings: rubber couplings connect pipes and fittings, providing a secure and flexible joint.

- Diaphragms: rubber diaphragms are commonly used in pumps to regulate the flow of water and sewage.

- Lining for Pipes and Tanks: rubber linings are applied to the interior surfaces of pipes and tanks to protect against corrosion and abrasion.

- Anti-Vibration Mounts: used to dampen vibrations in pumps and other equipment, reducing noise and preventing damage to the machinery.

- Rubber Membranes: in sewage treatment processes, rubber membranes are used in filtration systems to separate solids from liquids.

- Manhole Seals: rubber gaskets and seals are used in manhole covers and frames to prevent the infiltration of water and contaminants into the sewer system.

Polyurethane Moulding For The Water and Sewage Industry

The versatility of polyurethane allows for producing robust, lightweight, and corrosion-resistant components. Here are some common polyurethane components used in the water and sewage industry:

Pipe Linings: Polyurethane linings are applied to the interior surfaces of pipes to protect against corrosion and abrasion.

Seals and Gaskets: used to create tight and durable seals in water-related applications.

Pipe Coatings: Polyurethane coatings are applied to pipes to help extend their lifespan.

Pumps: Polyurethane is used in the manufacture of pump components such as diaphragms, wear rings, and seals.

Waterproofing Membranes: used to protect structures like water tanks, and reservoirs from water penetration.

Floatation Devices: such as floats and pontoons to provide support for various structures like pipes and platforms.

Water Treatment and Reservoir Components: such as membranes and seals in treatment equipment.

Rubber Covering including

- Rubber Rollers For The Water and Sewage Industry

- Rubber Wheels & Tyres The Water and Sewage Industry

Rubber covering provides a protective layer, extending the lifespan of components and the parts in which they are used.

Rubber Rollers

Polyurethane or rubber rollers are used in the water and sewage industry in various ways. They offer excellent wear resistance and load-bearing capacity.

Equipment they are used in includes:

Dosing Pumps – rubber rollers are used in dosing pumps that accurately dispense chemicals for water treatment processes.

Conveyor Systems – to transport equipment and materials

Roller screens – used to remove large debris and solids from wastewater and sludge

Material Handling – such as conveyor belts in sewage treatment plants

Rubber rollers can be custom-designed and used for specific applications, depending on the unique requirements of a project or operation.

Rubber Wheels

Wheels are used in various applications in the offshore and oil and gas industry.

These include:

- Trolleys to transport equipment

- Hoists and lifting equipment

- Material handling equipment

Rubber Extrusion For The Water and Sewage Industry

Rubber extrusion provides versatile solutions for sealing, insulation, and protection in various applications. Here are some common products which are made using the rubber extrusions process in the water and sewage sector:

Products include:

- Seals and Gaskets

- Cable Management Systems

- Expansion Joints

- Pipe and Cable Clamps

- Bumpers and Protectors

- Splash Guards

- Anti-Vibration Mounts

Rubber Sheets Conversion For The Water and Sewage Industry

Rubber sheet conversion offers numerous advantages to the offshore industry, proving to be a versatile solution for various applications. Our custom-cut rubber sheets provide excellent protection against corrosion, abrasion, and impact, extending the lifespan of critical offshore equipment and structures. Rubber sheeting is used in various applications in the water and sewage industry.

Typical uses for rubber sheet conversion include:

- Gaskets and Seals

- Lining for Tanks

- Insulation

- Matting

- Shock Absorption

- Membranes in Water Treatment Tanks

The specific type of rubber sheeting depends on the requirements of each application. Factors to consider include chemical exposure, temperature and abrasion.

Precision Engineering For The Water and Sewage Industry

Precision engineering is crucial in the water and sewage industry for several reasons, primarily due to the critical nature of water treatment, and sewage disposal processes. It is key to design, manufacture, and maintain equipment and systems that ensure efficiency, reliability, and compliance with environmental and safety standards.

With its high-level accuracy and attention to detail, precision engineering ensures the production of intricately designed rubber and polyurethane components, optimising performance and safety.