Custom Marine Rubber Component Manufacturer & Supplier

Clifton Rubber is a leading supplier to the marine and maritime industries. We manufacture various rubber components which provide multiple benefits to customers in these industries due to their unique properties, such as elasticity, longevity, anti-corrosion and water resistance. For marine buyers and ship builders alike, smooth sailing means choosing the right compounds. We supply custom-fit parts for a wide range of maritime vehicles including sailing boats, submarines, yachts, ferries, navy ships, tankers and many more.

Here are some common applications of rubber components in the marine and maritime industry:

- Fenders – to protect boats and ships during mooring and docking.

- Dock Bumpers – to protect vessels from impact.

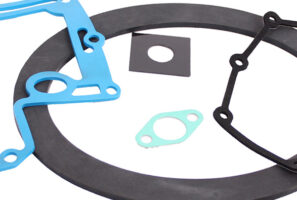

- Seals and Gaskets – to create water and airtight seals in areas such as doors, hatches and windows.

- Anti-Vibraton Mounts – to dampen vibration and reduce noise.

- Hoses and Tubes – built to withstand harsh marine conditions.

- Life Saving Equipment – rafts and buoys

From moulding processes to precision engineering, discover how these components play an essential role in various applications across the marine and maritime industries.

To find out more about each of our Capabilities in the Marine Industry…

Read MoreIndustrial Marine Rubber Component Manufacturing Services

Rubber Moulding For The Marine and Maritime Industry

Rubber moulded components are essential for ensuring the safety, longevity, and efficiency of marine systems and structures. These components are designed to withstand harsh marine conditions, including exposure to saltwater, UV radiation, and extreme weather.

Rubber moulded components commonly used in the marine and maritime industry include:

- Dock Buffers

- Plugs and Grommets

- Vibration Isolators

- Haul Off Blocks

- Boat Engine Seals

Polyurethane Moulding For The Marine and Maritime Industry

Polyurethane is being used more widely in marine applications as it replaces traditional plastics and rubbers – it can absorb vibration abrasion and is wear resistant in corrosive environments. It’s benefits include:

- Water Resistance

- Salt Water Resistance

- Ability to withstand water and harsh environments

- High load-bearing properties

- Great vibration and shock absorbing properties

- Tough and durable

- Weather and abrasion resistant in corrosive environments

Here are some common polyurethane moulded components used in the marine and maritime industry:

- Wheels and Castors

- Decking and Flooring

- Pipeline Protection

- Buoyancy Aids

- Dock Bumpers and Fenders

- Haul Off Blocks

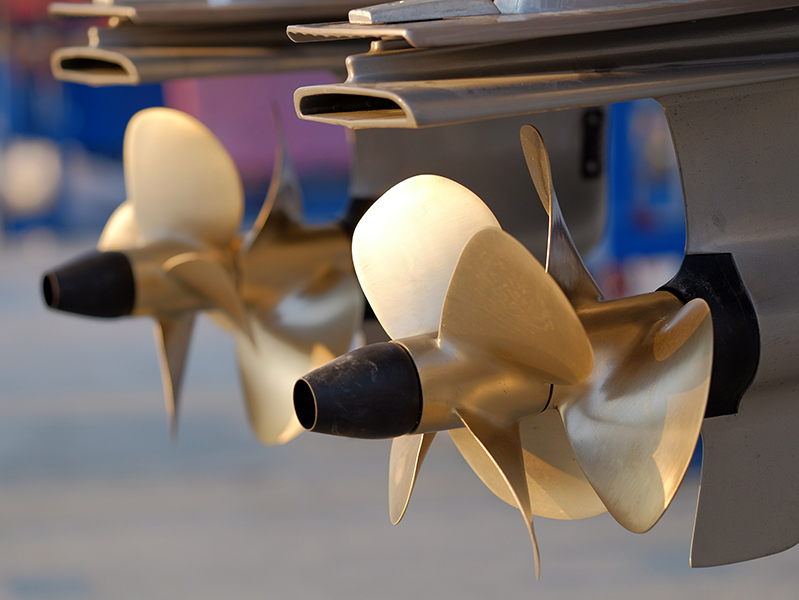

- Bow Thruster Blades

Polyurethane’s versatility and strength make it an ideal material for the marine and maritime industry.

Rubber Covering including

- Rubber Rollers For The Marine and Maritime Industry

- Rubber Wheels & Tyres The Marine and Maritime Industry

The use of rubber covering in the marine and maritime industry helps improve efficiency, reduce wear and tear on equipment, and enhance safety at marinas and ports..

Rubber covering, including rubber rollers, wheels, and tyres, brings significant advantages to the marine and maritime industry.

Rubber Rollers

Rollers provide exceptional traction and grip, facilitating the movement of heavy machinery and equipment with enhanced stability and control.

Rollers are used in various applications in the marine and maritime industry including:

- Conveyor Systems – used to move cargo in shipyards

- Mooring – used on docks to help the smooth mooring of vessels

- Lifting Equipment – for ship makers and cargo applications

- Towing – rollers are used to guide cables and towlines

Rubber Wheels and Tyres

Wheel and Tyres are used in various marine and maritime applications:

- On Ships

- On Ship and Dockyard Vehicles and Equipment

- On Cranes and Winches

- On Boat Trailers

- On Capstans

Rubber tyres and wheels, ensure safe, efficient, and comfortable travel for people as well as cargo and goods.

Rubber Covering solutions by Clifton Rubber offer excellent resistance to wear, tear, and chemicals, resulting in longer service life and reduced maintenance costs.

Rubber Extrusion For The Marine and Maritime Industry

Rubber extrusions cater to a wide range of applications in the marine industry. Boats, yachts, tug boats, and fishing vessels use parts such as rubber trim and seals. Naval and cargo ships also need door, window, and edge finish trim amongst other components.

Common uses of rubber extrusions in marine and maritime include:

- Window Seals

- Vibration Dampeners

- Seals, O Rings and Gaskets

- Hatch Seals

- Edge Trim

- Cabin & Compartment Seals

- Window Gaskets

- Tubing

Rubber Sheets Conversion For The Marine and Maritime Industry

Rubber sheet conversion allows rubber sheets to be custom-cut and moulded into various shapes, allowing for precise fabrication of vehicle components. From flooring mats to soundproofing materials, rubber sheets offer excellent anti-slip properties, enhancing safety within vessels.

They also act as protective layers for cargo, shielding it from damage during transportation. Their resilience and weather resistance make them ideal for a wide range of uses in the maritime and marine industry.

Here are some ways rubber sheeting is used in this industry:

- Decking and Flooring: Rubber sheeting is often used as flooring material for decks as it is slip resistant, cushioned and prevents noise and vibration..

- Gaskets and Seals: Used to create gaskets and seals for doors, hatches, windows etc.

- Vibration Isolation: Can be used as isolators or dampers to reduce vibration and noise.

- Bumper and Dock Protection: Used as a protective material on loading docks and bumpers to cushion the impact of vehicles during loading and unloading, reducing damage to both the vehicles and the infrastructure.

- Anti Fouling Applications: Rubber sheeting can be used as a protective layer on ship hulls to inhibit the growth of marine organisms such as barnacles and algae.

Precision Engineering For The Marine and Maritime Industry

Precision engineering plays a pivotal role in the marine and maritime industry. With its high-level accuracy and attention to detail, precision engineering ensures the production of intricately designed rubber and polyurethane components.

Precise manufacturing processes lead to higher quality components meaning reduced wear and tear, extending the lifespan of equipment and lowering maintenance costs.

Precision Engineering is widely used in other areas of the marine and maritime industry as it is vital for areas such as engine manufacture, navigation and control systems, hydraulic systems, automation and robotics.

Our precision engineering division maintains a comprehensive engineering capability providing in-house and sub-contract toolmaking, machining and fabrication services.