Custom Renewable Energy Rubber Component Supplier & Manufacturer

Clifton Rubber supplies products to the world’s energy creating industries including renewables and power. The nature of the industry means that product durability and resistance to harsh weather conditions is key. Our products are used for various onshore and offshore power applications such as:

- Turbine Blade Masks

- Solar Panel Mounts

- Cable Protectors

- Pipe Seals

- Piggy Back Clamps

and many more…

Clifton Rubber has an industry leading rubber and polyurethane manufacturing facility based in Cambridgeshire. Clifton Rubber is ISO 9001 accredited and adheres to strict quality procedures ensuring our products meet the demanding specifications and quality assurances, in addition to resisting the harsh environmental factors present in the renewables and power industry.

To find out more about each of our Capabilities in the Renewables and Power Industry…

Read MoreIndustrial Renewable Energy Rubber Component Manufacturing Services

Rubber Moulding For The Renewables and Power Industry

The rubber moulding process enables the creation of custom-designed rubber components that withstand harsh high pressure environments, including corrosion, extreme temperatures, and saltwater.

Our flexibility in design and production allows customers to adapt to evolving requirements, enhancing overall productivity and reliability.

Typical rubber moulded components used in the industry include:

Cable and Pipe Clamps and Seals: used extensively in offshore equipment and structures to create watertight and airtight seals, and/or hold in place pipes and cables.

Rubber Bumpers and Fenders: Rubber bumpers and fenders are used on offshore platforms and vessels to absorb impact and prevent damage during docking and mooring. They are also used on equipment to protect against accidental collisions. Also they are used in offshore equipment and structures to accommodate movement and absorb forces caused by wind, waves, and currents.

Weatherproofing: Rubber moulded components are resistant to weather and corrosion, making them suitable for use in harsh environments, which is particularly important in power plants.

Flexible Connectors: Rubber connectors are used in power transmission systems absorb shocks and vibrations, and ensure the longevity of equipment.

- Solar Panel Mounts and Supports: Rubber components are often used in the mounting and support systems for solar panels. They protect the panels in varying weather conditions.

Clifton Rubber can always help with the design and manufacture of custom moulded components that meet your exact specification.

Polyurethane Moulding For The Renewables and Power Industry

The versatility of polyurethane allows for producing robust, lightweight, and corrosion-resistant components. Its lightweight and durable nature makes it suitable for creating long, aerodynamic blades that can withstand the harsh environmental conditions associated with wind energy generation.

- Wind Turbine Blades: Polyurethane can be used in the manufacturing of long, aerodynamic blades that can withstand the harsh environmental conditions associated with wind energy generation.

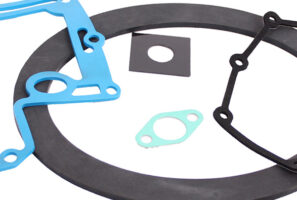

- Seals and Gaskets: to provide effective sealing to prevent leaks.

- Coatings: Polyurethane coatings are used to protect cables and wires in the power industry. These coatings provide insulation and protection.

- Insulation and Vibration Dampeners: to help reduce the impact of vibrations in power generation equipment, such as generators and turbines.

- Cable and Pipe Clamps and Seals: used extensively in offshore equipment and structures to create watertight and airtight seals, and/or hold in place pipes and cables.

- Concrete Repair and Protection: Polyurethane coatings are employed for repairing and protecting concrete structures in power plants.

The use of polyurethane components contributes to the efficiency, durability, and reliability of equipment and infrastructure in the renewables and power industry.

Rubber Covering including

- Rubber Rollers For The Renewables and Power Industry

- Rubber Wheels & Tyres The Renewables and Power Industry

Rubber covering protects equipment and structures against weather, saltwater, chemicals, and abrasive elements.

Rubber Rollers

Polyurethane is chosen for components that experience high wear and abrasion, such as conveyor belts and rollers used in power plants. Its resistance to wear and tear helps in extending the lifespan of these components.

Polyurethane or rubber rollers are used in material handling equipment, such as conveyors, to transport heavy pipes, turbine blades, other equipment and materials, due to their versatility, durability, and ability to provide traction and grip.

Equipment they are used in includes:

Winches and Rope handing – to guide cables.

Conveyor Systems – to transport equipment and materials

Mooring Systems – to maintain stability

Pipeline Inspections – used in equipment for testing pipelines

Rubber rollers may be custom-designed and used for specific applications, depending on the unique requirements of a project or operation.

Rubber Wheels

Wheels are used in various applications in the renewables and power industry.

These include:

- Trolleys to transport tools and equipment

- Cranes and Hoists

- Mobile Platforms

Rubber Extrusion For The Renewables & Power Industry

Rubber extrusion plays a vital role in sealing, insulation, and protection against environmental elements.

Products include:

- Seals and Gaskets

- Cable Management Systems

- Weather Seals

- Mounts and Supports

- Pipe and Cable Clamps

- Bumpers and Protectors

Rubber Sheets Conversion For The Renewables and Power Industry

Rubber sheeting is used in various applications in the renewables industry, primarily due to its properties such as flexibility, insulation, and resistance to environmental factors.

Rubber sheeting contributes to the performance, durability, and reliability of equipment. Our custom-cut rubber sheets provide excellent protection against corrosion, abrasion, and impact, extending the lifespan of critical power equipment and plant machinery.

Typical uses for rubber sheet conversion include:

Matting

Shock Absorption

Vibration Dampening

Seals

Insulation

Rubber sheets with specific chemical and oil-resistant properties are used in areas where exposure to corrosive chemicals or hydrocarbons is a concern, such as in chemical storage areas or near drilling operations.

Precision Engineering For The Renewables and Power Industry

The design and manufacturing of precision-engineered components ensure optimal performance, reliability, and safety in the renewables and power components.

The nature of the industry means these precisely crafted parts withstand extreme environmental conditions – corrosion, weather, extreme temperatures.

With its high-level accuracy and attention to detail, precision engineering ensures the production of intricately designed rubber and polyurethane components, optimising performance and safety.

Essentially precision engineering allows the renewables and power industry to achieve higher standards of quality, cost-effectiveness, and overall excellence.