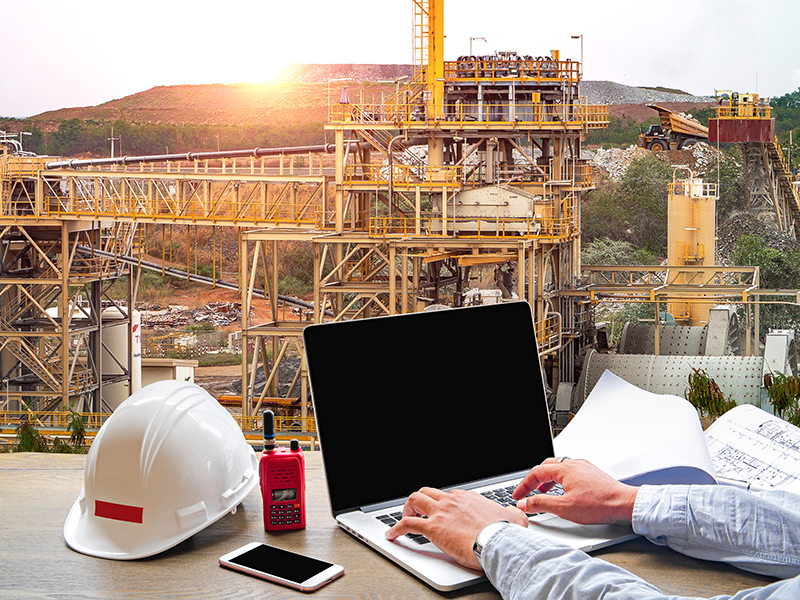

Custom Mining Equipment Rubber Parts Manufacturer & Supplier

For over 50 years Clifton Rubber has been a specialist rubber & polyurethane manufacturer. Clifton Rubber is ISO 9001 accredited and as such adheres to strict quality procedures ensuring our products meet the demanding specifications and quality assurances required by the mining and quarrying industry, due to the challenging environments in which the industry operates.

We have manufactured various bespoke rubber components for use by our customers in this sector, such as anti static rollers, polyurethane screening mats, rubber sheets and conveyor rollers.

From moulding processes to precision engineering, discover how these components play an essential role in enhancing the mining and quarrying industry.

To find out more about each of our Capabilities in the Mining & Quarrying Industry…

Read MoreIndustrial Mining Equipment Rubber Parts Manufacturing Services

Rubber Moulding for the Mining and Quarrying Industry

The mining and quarrying industry utilises various rubber-moulded components for a wide range of applications due to the abrasive and challenging environments in which they operate. Clifton Rubber’s products provide cost-effective solutions, allowing mass production of identical components, and reducing downtime and maintenance expenses.

Our design and production flexibility allows us to adapt to our customers evolving requirements, enhancing overall productivity and reliability.

Typical rubber moulded components include:

- Conveyor Belts: Rubber conveyor belts to transport mined materials and designed to withstand heavy loads and harsh conditions..

- Impact Pads: These components are used on conveyor belts to absorb the shock and impact of materials being loaded onto the belt.

- Rubber Linings: Rubber lining is used to protect equipment such as chutes, and pipes from wear and tear caused by the movement of mined materials, thereby reducing maintenance.

- Rubber Hoses and Hose Fittings: for example to transport water, and hydraulic fluids. Rubber hose fittings are used to connect hoses.

- Conveyor Rollers: to move materials around the work site.

Rubber-moulded components used in the mining and quarrying industry help to ensure the safe functionality of equipment and workers in harsh and abrasive environments, used for wear, abrasion and impact resistance. All our bespoke rubber products are designed with safety and longevity in mind.

Polyurethane Moulding for the Mining and Quarrying Industry

The versatility and durability of polyurethane allows for producing hard wearing yet lightweight components that are ideal for use in the harsh environments in which the mining and quarrying industry operates. Some typical PU components that are used in this industry include:

- Vibration and Noise Dampening: Polyurethane is used to create vibration isolators and dampeners for machinery and equipment, reducing vibrations and increasing the lifespan of the machinery.

- Pipe and Shute Linings and Coatings: Used as a lining or coating material for pipes to transport liquid and chutes to transport mined materials.

- Protective Coatings and Linings: Polyurethane coatings and linings are used to protect surfaces from corrosion, abrasion, and chemical exposure.

- Bollards and Traffic Safety Products: Polyurethane is used to create traffic safety products.

- Polyurethane Screen Mats: used in vibrating screens and sieves to classify and separate different sizes of materials.

The customizability and rapid production of polyurethane moulded parts enable the quick turnaround of poly moulded components, contributing to increased operational efficiency and enhanced safety in quarrying operations.

Rubber Covering including

- Rubber Rollers for the Mining and Quarrying Industry

- Rubber Wheels & Tyres for the Mining and Quarrying Industry

Rubber covering, including rubber rollers, wheels, and tyres, brings significant advantages to the mining and quarrying industry.

Rubber rollers provide exceptional traction and grip, facilitating the movement of heavy machinery and quarrying equipment with enhanced stability providing cushioning in the movement of materials and equipment. .

Rollers are used in various applications in the industry including:

- Rollers: Polyurethane rollers are used in equipment Material Handling Equipment such as conveyor systems and feeders. Different types of rollers are used for different applications such as: Conveyor Rollers – to support and guide conveyor belts, Return Rollers – used under a conveyor roller for support, Transition Rollers – to help a belt change either direction or height.

- Cranes and Lifts: To support heavy loads and ensure smooth movement along tracks and rails.

- Screening and Vibrating Equipment: Used in screeners, trommels and other material handling equipment.

- Crushing Equipment – crushers and screeners may use rollers as part of the process to break down or separate materials.

Rollers offer excellent shock absorption, reducing vibration and minimising damage to both equipment and materials.

Rubber Wheels and Tyres

Wheels are used in various applications in the mining and quarrying industry.

These include:

- Trolleys to transport material and equipment

- Cranes and Hoists

- Mobile Crushing and Screening Plant

- Safety barriers

- Mining vehicles – trucks and other transportation equipment

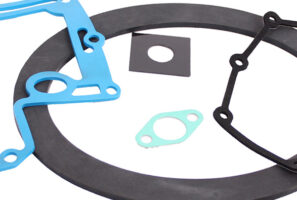

Rubber Extrusion for the Mining and Quarrying Industry

Rubber extrusions are valuable in the mining industry for their durability, flexibility, and resistance to environmental factors.

These are used for sealing, insulation, and protection against environmental elements, ensuring watertight and reliable connections. Their versatility enables the development of complex shapes, contributing to improved design options and enhanced performance.

Products include:

- Seals and Gaskets

- Cable Management Systems

- Vibration Dampening

- Pipe and Cable Clamps

- Bumpers and Protectors

- Safety Barriers

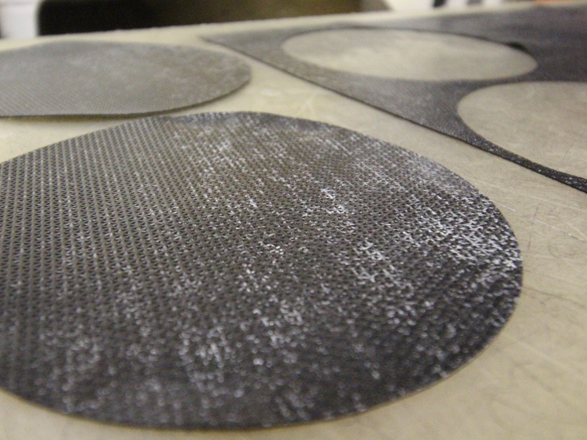

Rubber Sheet Conversion for the Mining and Quarrying Industry

Rubber sheet conversion is a versatile solution for various applications within the mining and quarrying industry . Our custom-cut rubber sheets provide excellent protection against corrosion, abrasion, and impact, extending the lifespan of critical mining equipment.

Typical uses for rubber sheet conversion include:

- Seals and Gaskets

- Insulation

- Matting

- Shock Absorption

- Dust Control

The type of rubber sheeting used depends on factors such as material composition, thickness, and hardness, abrasion, and chemicals it will be exposed to.

With its high-level accuracy and attention to detail, precision engineering ensures the production of intricately designed rubber and polyurethane components, optimising performance and safety.

The Mining and Quarrying industry can achieve higher standards of quality, cost-effectiveness, and safety by using precision engineered components in its equipment

It involves the production of high-precision components and equipment using advanced techniques and technologies. At Clifton Rubber our precision engineering capability offers customization and versatility, allowing for tailored solutions to specific requirements.

Clifton Rubber offers a range of Bespoke Rubber Components for various industry sectors, including mining and quarrying. Our custom made products for your industry include:

We also provide Custom Polyurethane solutions tailored to specific industry needs.