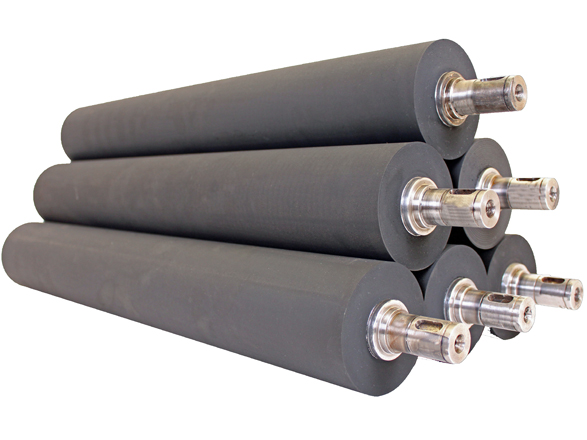

Custom Rubber Roller Coating & Manufacturer Services

With over 50 years of expertise in manufacturing, covering, and refurbishing rubber rollers, Clifton Rubber is your trusted partner for all your rubber roller needs.

We offer a comprehensive range of services tailored to your requirements

Rubber Roller Covering Capabilities

At Clifton Rubber, we provide a one-stop shop for all your rubber roller requirements. Our state-of-the-art roller covering and precision engineering equipment, combined with our in-house capabilities, enable us to offer a complete rubber roller manufacturing service. Our capabilities include:

Manufacturing new rubber-covered rollers: We can manufacture complete new rubber rollers, including steel, aluminum, or plastic drums and shafts.

Covering customer-supplied roller drums and shafts: If you have existing roller drums and shafts, we can apply rubber coverings to them, ensuring optimal performance.

Refurbishing worn rubber-covered rollers: We offer refurbishment services for worn rubber rollers. This includes stripping and replacing the existing rubber covering or re-grinding the surface to restore functionality.

We are with you every step of the way

Rubber Roller Covering Service

To make your experience seamless, we provide a hassle-free roller collection and delivery service. We have our own transport network, or we can arrange collection through our trusted logistics partners. Our goal is to offer a fast and reliable roller covering service, accommodating quick turnarounds for breakdown situations.

Our advanced covering, curing and grinding equipment mean we can cover rollers up to 8 meters in length and 3 metres in diameter.

Rollers can be ground to various profiles using our state-of-the-art CNC equipment including: Smooth Parallel Ground, Crowned Ground, Tapered Ground, Polished Finish or alternatively we can supply rollers with Plain Finish,

We can also groove rollers in various patterns including: Helical Groove, Diamond Pattern, Lineal Groove, Spiral Groove, Castellated, Chevron Grooved and Herringbone Groove.

Roller Engineering Service

Our in-house precision engineering division has the latest in CNC machining and fabrication equipment and a team of experienced precision engineers. This in-house engineering capability allow us to keep control of quality and lead times for all our customer’s roller projects.

Our engineering team can manufacture complete new rollers from most engineering materials such as mild steel, stainless steel, aluminium or engineering plastics including nylon and polypropylene. We can also offer an in-house repair service for damaged roller drums, shafts, journals and keyways.

Rubber Roller Materials

We use high quality ethically sourced rubber compounds to cover rollers including but not limited to:

- Natural Rubber (NR)

- Ebonite

- SBR

- Neoprene

- Nitrile

- EPDM

- Hypalon

- Silicone

- Polyurethane

Our polymer compounds can be specified to meet specific performance criteria including food quality, anti-static, conductive and fire retardant.

Roller Applications

The industries we work in are wide ranging including agriculture, pharmaceuticals, food and drink processing, print and packaging, recycling, aerospace and construction to name but a few. Typical roller covering applications include:

- Conveyor Drive and Idler Rollers

- Print Rollers

- Steel Processing Rollers

- Heavy Duty Rollers

- Transfer Rollers

- Materials Handling Rollers

- Agricultural Rollers

- Laminating Rollers

- Squeegee Rollers

- Food Processing Rollers

- Industrial Rollers

- Packaging Rollers

Why Use Clifton Rubber?

Clifton Rubber’s roller covering service is regarded as the best in industry for quality and value. Our rollers are guaranteed, so you can be assured of our commitment to keep your equipment running. Our expert team have accumulated many years’ experience in manufacturing and covering rollers and can advise on any issues or queries including material specifications, roller design or end use applications.

We maintain a certified quality system to ISO9001:2015 to ensure our rubber rollers meet our high-quality standards every time.

Contact us today to discuss your roller covering requirements or book a collection.