Custom Recycling Industry Rubber Component Manufacturer & Supplier

Clifton Rubber is a growing brand in the UK and European recycling and waste management industry supplying high quality rubber and polyurethane components to some of the industry’s leading Original Equipment Manufacturers.

We manufacture and supply a range of standard components and replacement parts. These include rubber and polyurethane stars and discs suitable for all major types of screening plant, as well as trommel wheels, conveyor rollers, idler discs and polyurethane screens.

In addition to our stock replacement components, we are able to manufacture customer bespoke parts from rubber or polyurethane, using our in house manufacturing capabilities.

The recycling industry relies heavily on durable, efficient materials to ensure smooth operations. Two of the most vital materials used in this industry are rubber and polyurethane, both of which have properties that are ideal for manufacturing components which withstand the challenges of waste management and recycling applications.

From moulding processes to precision engineering, discover how these components play an essential role in enhancing the recycling process.

To find out more about each of our Capabilities in the Recycling Industry…

Read MoreCustom Recycling Industry Rubber Component Manufacturing Services

Rubber Moulding for the Recycling Industry

Rubber-moulded products have unique properties including durability, resistance to chemicals, and the ability to withstand harsh environments. All of these properties are ideal for the waste and recycling industry, where rubber moulded components are used in products such as:

- Recycling Sorting Equipment: Rubber components, such as conveyor belts and rollers, are used in recycling sorting equipment such as picking stations.

- Waste Compactors: Rubber seals and gaskets are used in waste compactors to prevent leakage.

- Other Recycling Machinery: such as shredders and baler equipment.

- Protective Clothing and Accessories.

- Safety Mats and Flooring: Rubber mats and flooring are used in waste sorting and processing areas to provide anti-slip surfaces and ergonomic support for workers.

- Dustbins and Skip Liners: Rubber liners are used inside dustbins and skips to facilitate the easy removal and disposal of waste materials.

Rubber moulded products in the waste and recycling industry improve durability, reduce maintenance costs, improve safety, and contribute to more efficient waste management and recycling practices.

Polyurethane Moulding for the Recycling Industry

Polyurethane moulded components are widely used in the waste and recycling industry. They are lightweight, durable and resistant to wear and tear, heat and chemicals.

They are widely used in the industry but typically uses include:

- Conveyor Belts and Rollers: Polyurethane’s wear-resistant properties make it suitable for handling abrasive materials and ensuring smooth material flow.

- Sorting and Separation Equipment: Sorting equipment, such as discs, stars, and screens, to efficiently separate different types of recyclable materials.

- Wear Liners: used to line chutes, hoppers, and other equipment, protecting them from the impact and abrasion of waste materials.

- Gaskets and Seals: used in various waste handling equipment.

- Wheels and Tyres: in the manufacture of tyres and wheels.

- Shock Absorbers and Bumpers: to protect and limit damage.

The use of polyurethane moulded components in the waste and recycling industry results in durability, less maintenance, and better performance for equipment and machinery.

Rubber Covering including

- Rubber Rollers for the Recycling Industry

- Rubber Wheels & Tyres for the Recycling Industry

Rubber covering is widely used in the recycling industry due to its protective and wear-resistant properties. It can help to improve the longevity of equipment and improve efficiency in the recycling process.

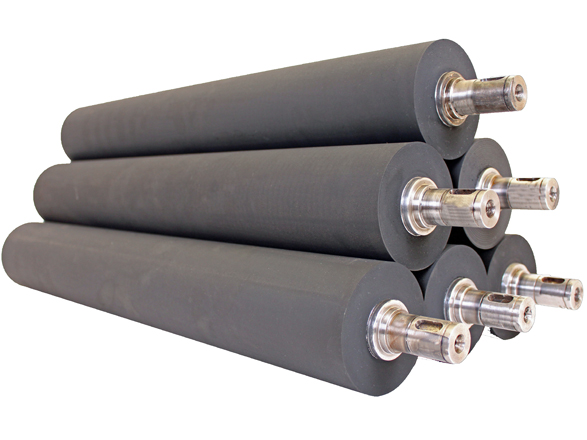

Rubber Rollers

Rubber rollers are widely used in the recycling industry due to their ability to transport, sort, and process various materials effectively. Here are some common uses of rubber rollers in the recycling industry:

- MRF Conveyor and Sorting Systems: to transport recyclable materials between different processing stages or to sort and divert materials (for example, paper, metals, wood) into separate bins.

- Shredders and Baler Machines: to feed materials into the grinding or baling mechanisms.

- Trommel Screens: Rubber rollers are used in trommel screens to facilitate the separation of materials by size.

- Glass Crushing Machines: Rubber rollers can be used in glass crushing machines to feed glass for crushing.

Overall, rubber rollers in the recycling industry play a vital role in optimising the material handling and sorting processes.

Rubber Wheels and Tyres

Rubber wheels and tyres are used in the recycling industry in areas such as:

- Forklifts and Loaders

- Recycling and Dumper Trucks

- Other Waste Transporting Trucks

- Recycling Containers

- Mobile Screening Plant

The durability and versatility of rubber wheels and tyres make them suitable for various recycling applications.

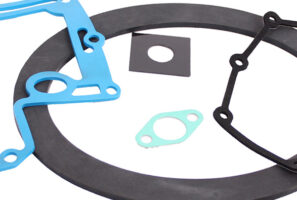

Rubber Extrusion for the Recycling Industry

Rubber extrusion stands as a significant asset to the recycling industry, amplifying its positive impact on sustainability. Through this process, rubber can be transformed into various profiles, sheets, and tubes, paving the way for various applications across the industry.

Here are some common uses of rubber extrusions in the waste and recycling industry:

- Seals and Gaskets: for waste containers, bins, and hoppers to prevent leakage and contamination.

- Wear Strips and Impact Bars: in conveyor systems and chutes to protect material.

- Bumpers: to prevent damage.

- Conveyor Belts Skirting and Cushioning: preventing material loss from machinery

- Noise Dampening: to reduce noise levels in recycling equipment

These extruded rubber components enhance recycling processes, minimising material loss, reducing wear on equipment, and contributing to more sustainable waste management practices.

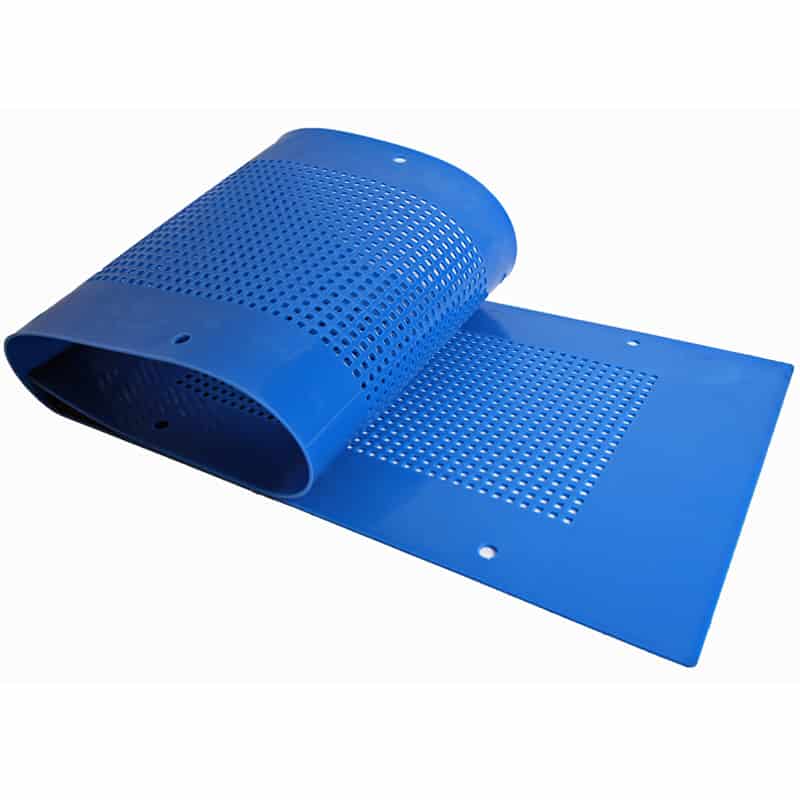

Rubber Sheet Conversion for the Recycling Industry

Rubber sheet conversion brings invaluable advantages to the recycling industry, bolstering its efforts towards sustainability and resource conservation. This process allows for the transformation of rubber into flat sheets of various thicknesses and sizes. These sheets serve as the foundation for manufacturing new products, ranging from gaskets and seals to flooring and other applications.

Some applications of rubber sheet conversion in the waste and recycling industry are:

- Gaskets and Seals

- Liners

- Impact Pads and Anti-Vibration Components

- Conveyor Skirting and Curtains

- Wear Parts

- Mats and Flooring

By using rubber sheet conversion, the waste and recycling industry can optimise equipment performance and produce the right component parts for its machinery.

- Precision Engineering For The Recycling Industry

Through precision engineering techniques, recycling centres can optimise sorting and processing methods, ensuring accurate separation of various materials. This results in higher-quality recycled products with reduced contamination, making them more desirable for manufacturers and consumers. Precision engineering also enables the creation of advanced recycling machinery and equipment, enhancing overall recycling capabilities and throughput.

Embracing precision engineering empowers the recycling industry to achieve higher recycling rates, reduce environmental impact, and drive a more circular and sustainable economy.