Custom Rubber Gasket & Seal Manufacturing Services

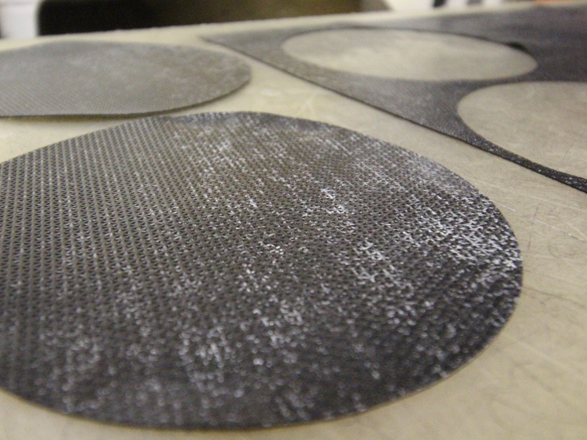

Clifton Rubber is a leading rubber sheet converter. We convert rubber sheeting to produce customer bespoke rubber gaskets, rubber seals and various other non-metallic washers, gaskets, seals, insulations and sheeting.

Ourrubber gaskets are manufactured to the customer’s design and can be produced in all shapes and sizes to meet even the most obscure requirements. Most rubber gasket products are cut from rubber sheet materials, but we can also manufacture fully moulded gaskets and seals and can supply parts with a self-adhesive backing of any length, width or thickness.

With over 50 years of experience in the industry, we work hard to achieve the most competitive prices for our customers whilst maintaining our industry leading quality assurances. We utilise a variety of rubber conversion tools and techniques which allow us to convert rubber into high quality, bespoke products to meet a customer’s exact requirements.

Our Rubber Sheet Conversion process has various advantages:

- Less wastage - reduces material costs

- Versatile – ideal for simple and complex projects

- Scale - Available for small to large production runs

- Bespoke – we can manufacture to your exact requirements

- Project management – we work with you at every stage of your project

Our History and Expertise

Since 1973 we have developed significant technical expertise in the conversion of rubber sheeting. Our expert team can advise on any issues or queries you may have.

To maintain a quality product and service we put quality at the heart of our processes. Our quality management system is therefore certified to ISO9001.

The Rubber Sheet Products Produced

Always striving to meet customer requirements, the most regularly manufactured products we supply include:

- Neoprene Gaskets

- Viton Gaskets

- EDPM Gaskets

- Foam Gaskets

- Neoprene Seals

- Viton Seals

- EDPM Seals

- Foam Seals

- Neoprene Washers

- Form Strips

- Rubber Strip

- Silicone Strip

- Rubber Sheet

- Foam Pads

Rubber Gasket Materials

We manufacture rubber gaskets and rubber seals from all commercially available rubber and other non-metallic materials and in a range of hardnesses, shapes & sizes and colours to suit customer requirements.

Common materials we process include:

- Natural Rubber (NR)

- SBR - Styrene-butadiene rubber (SBR)

- EPDM – EPDM rubber (ethylene propylene diene monomer rubber)

- Neoprene (Polychloroprene)

- Hypalon

- Nitrile (NBR)

- Fluorocarbon Rubbers (FKM/FPM)

- Silicone (MQ, VMQ, PVMQ, FVMQ)

Materials can be stipulated to meet more specific user requirements including:

- High and Low Temperature

- WRAS Approved

- Flame Retardant

- Chemical resistant

- Anti-Static

- FDA/Non-Toxic

Find out more about our other Capabilities

Companies We've Worked With

Industries We Work In

We create bespoke and custom rubber mouldings for use in specific industry applications. Our rubber products and mouldings are trusted by many of the world’s leading companies for use in some of the harshest environments, across a range of different industries:

Rubber Sheet Conversion FAQs

-

What is rubber sheet conversion?

Rubber sheet conversion is the process of converting rubber sheeting to produce bespoke end products for many different applications to suit our customer’s needs.

-

What types of rubber sheet products can your company produce?

Our typical products include rubber gaskets, rubber seals and various other non-metallic washers, gaskets, seals, insulations and sheeting.

-

What materials can you manufacture rubber gaskets and seals from?

We can manufacture from a range of materials including:

- Natural Rubber (NR)

- Styrene-butadiene rubber (SBR)

- EPRM

- Neoprene

- Hypalon

- Nitrile (NBR)

- Fluorocarbon Rubbers (FKM/FPM)

- Silicone

-

What is the typical lead time for a rubber sheet conversion order?

We typically turn around a product within 3 to 4 weeks from placement of the order.

-

Can you create bespoke rubber gaskets and seals to fit my specific needs?

Yes we can. Our rubber gaskets are manufactured to the customer’s design and can be produced in all shapes and sizes to meet even the most obscure requirements.

-

What is the process for ordering rubber sheet conversion products from your company?

Get in touch with our Friendly Technical Sales Team who will be with you every step of the way.

-

What is the difference between neoprene, viton, and EDPM materials in terms of rubber gaskets and seals?

The primary differences between these rubber materials is in their chemical resistance and temperature ranges.

VITON is a synthetic rubber and fluoropolymer elastomer. “Fluoropolymer” means this material has high resistance to solvents, acids, and bases. “Elastomer” is a word that is basically interchangeable with “rubber.”

Advantages:

- Withstands high temperatures

- Withstands a wide range of chemicals – oils, gases, silicone fluids and mineral acids

- Good electrical properties and low burning characteristics

- Good in harsh environments – resistant to weather, UV exposure, oxidation, fungus and mould

Disadvantages:

- Expensive

- Poor performance at low temperatures

- Decomposes under excessively high temperatures

EDPM is ethylene-propylene-diene-monomer. It is a synthetic rubber compound made from the chemicals in its name and is used in many applications.

Advantages:

- Strong resistance to hot and cold temperatures

- Excellent weathering properties – ozone and sunlight resistant

- Excellent tear abrasion

- Lightweight and long lasting

- Water resistant

Disadvantages:

- Poor resistant to petroleum based fuels, most oils, gasoline, kerosene, aromatic and aliphatic hydrocarbons, solvents and acids

NEOPRENE

Neoprene (also polychloroprene) is a family of synthetic rubbers that are produced by polymerization of chloroprene.

Advantages:

- Impermeability

- Elasticity

- Good resistance to water

- High tensile strength properties

- Better flame retardant properties

Disadvantages:

- Higher cost

- Poor resistance to strong oxidising acids, esters, ketone and certain hydrocarbons.

Each of these three materials are considered to be excellent all-purpose fabrics. However, commonly EPDM is an excellent choice for outdoor applications and is a popular choice within the automotive industry. Neoprene is a popular choice for its flame retardant capabilities, oil resistance and overall durability. Viton has good durability.

-

How does your quality management system ensure a high-quality product?

To maintain a quality product and service we put quality at the heart of our processes. We work with you every step of the way – from initial consultation, to design, production and delivery. Our quality management system is therefore certified to ISO9001.