Custom Rubber Component Manufacturer & Supplier for the Construction Industry

Rubber and polyurethane components play a crucial role in the construction industry by contributing to various building and infrastructure projects. The versatility of rubber makes it a valuable material for addressing a wide range of construction challenges.

Clifton Rubber is a leading supplier to the construction sector. We have manufactured various bespoke rubber components for use by our customers in this sector, such as moulded washers for cab systems, suction nozzles for road sweeping equipment and protective bump stops.

In addition we manufacture and supply a range of standard own brand products for general use in the construction industry such as brick grabs and loading bay buffers.

From moulding processes and extrusion to precision engineering, discover how these components play an essential role in enhancing the construction industry.

To find out more about each of our Capabilities in the Construction Industry…

Read MoreCustom Construction Rubber Component Manufacturing Services

Rubber Moulding For The Construction Industry

Rubber moulding provides excellent sealing properties, ensuring air and water tightness in various construction applications due to rubber’s ability to withstand challenging environmental conditions. Additionally, rubber moulded components offer resistance to extreme temperatures, chemicals, and UV radiation, enhancing their durability and longevity.

Here are some common uses of rubber moulded components in construction:

- Seals and Gaskets: Rubber seals and gaskets are used in construction to create airtight and watertight seals between building components, for example: windows, doors and roofing.

- Vibration Isolators and Dampers: Rubber moulded components can be used to isolate and dampen vibrations in construction equipment and structures.

- Pipe Seals and Couplings: Rubber moulded components are used in sealing pipe connections and couplings, preventing water leaks and ensuring the integrity of plumbing systems.

- Roadway and Bridge Expansion Joints: Rubber expansion joints are used in road and bridges construction.

- Noise Insulation: To reduce sound in buildings, helping to create quieter and more comfortable living and working spaces.

- Rubber Tracks for Heavy Equipment: Construction machinery like excavators use rubber tracks, providing better traction,while minimising damage to paved surfaces.

- Protective Bumpers: Protective bumpers and guards are used on heavy equipment and machinery to prevent damage caused by impacts and collisions.

Rubber moulded components contribute to efficiency, safety, and durability in the construction industry . Furthermore, rubber moulding allows for complex shapes and designs, enabling precise customisation for construction projects.

Polyurethane Moulding For The Construction Industry

Polyurethane moulding offers exceptional versatility, allowing for the production of intricate shapes, textures, and sizes, thus enabling customised architectural elements and decorative accents.

Polyurethane moulded components exhibit high durability, with resistance to abrasion, impact, and weathering, making them suitable for various construction applications such as:

- Columns, balusters, cornices, and mouldings: Polyurethane is used to produce ornamental columns, decorative trims, mouldings, and cornices that add elegance and sophistication to building exteriors and interiors.

- Roofing Materials: Polyurethane moulded components are used in roofing as they are durable and weather-resistant.

- Vibration Dampening: Polyurethane is used to create vibration isolators and dampeners for construction machinery and equipment, reducing vibrations and increasing the lifespan of the machinery.

- Pipe Linings and Coatings: Used as a lining or coating material for pipes, in plumbing and drainage systems.

- Protective Coatings and Linings: Polyurethane coatings and linings are used to protect concrete surfaces from corrosion, abrasion, and chemical exposure.

- Bollards and Traffic Safety Products: Polyurethane is used to create traffic safety products.

Additionally, polyurethane moulding is lightweight, facilitating easy installation and reducing the load on structures. It also offers thermal and sound insulation properties, enhancing energy efficiency and creating a comfortable environment.

Polyurethane is low maintenance, requiring minimal upkeep and providing long-lasting performance. Overall, it contributes to the aesthetic appeal, functionality, and cost-effectiveness on construction projects.

Rubber Covering including

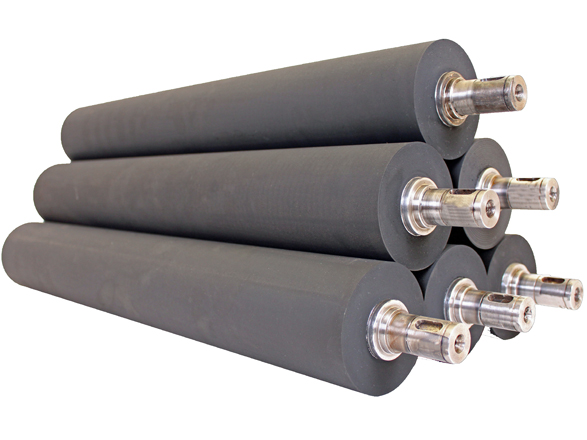

- Rubber Rollers For The Construction Industry

- Rubber Wheels & Tyres For The Construction Industry

Rubber covering, including rubber rollers, wheels, and tyres, brings significant advantages to the construction industry.

Rubber rollers provide exceptional traction and grip, facilitating the movement of heavy machinery and construction equipment with enhanced stability and control.

Rollers are used in various applications in the construction industry including:

- Compactors and Rollers: Polyurethane rollers are used in compaction equipment and road rollers. They provide efficient compaction of soil, asphalt, and other construction materials, helping to create stable and durable surfaces for roads, pavements, and foundations.

- Material Handling Equipment: Such as conveyor systems.

- Cranes and Lifts: To support heavy loads and ensure smooth movement along tracks and rails.

- Scaffolding: Polyurethane rollers are used in scaffold systems equipment to allow for easy movement of materials and equipment during construction and maintenance activities.

- Bridge Construction: Polyurethane rollers are used in bridge construction to support heavy loads and provide smooth movement of bridge components during installation.

- Pile Driving Equipment: Polyurethane rollers are used in pile driving equipment to support and guide piles during installation.

They also offer excellent shock absorption, reducing vibration and minimising damage to delicate surfaces during construction operations.

Rubber wheels and tyres provide superior load-bearing capacity, ensuring smooth transportation of materials on various terrains. Their elasticity and resilience contribute to a comfortable ride and improved safety.

They are typically used in:

- Construction Vehicles: such as excavators, concrete mixers and dumper trucks

- Construction Equipment: such as cranes, forklifts, and concrete mixers.

Rubber covering solutions offer excellent resistance to wear, tear, and chemicals, resulting in longer service life and reduced maintenance costs. Overall, rubber covering enhances productivity, efficiency, and safety in construction projects.

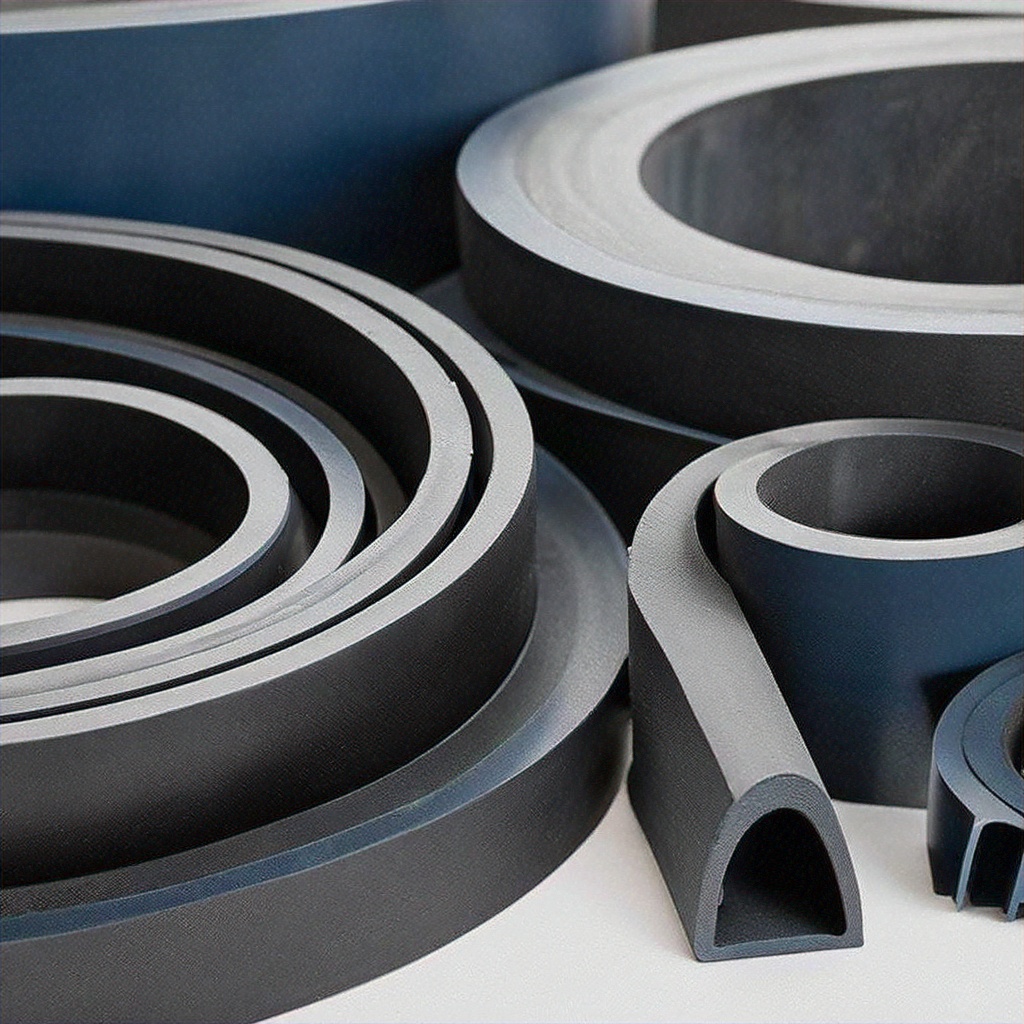

Rubber Extrusion For The Construction Industry

Rubber extrusion enables the production of custom rubber profiles, such as seals, gaskets, and weatherstripping, which are essential for maintaining air and water tightness in buildings.

These profiles offer superior resistance to extreme temperatures, UV radiation, and chemicals, ensuring long-lasting performance and durability.

Common uses of rubber extrusions in construction:

- Weather Stripping: Rubber extrusions are used as weather stripping around windows, doors, to provide a tight seal and prevent air and water infiltration.

- Seals and Gaskets: Rubber extrusions are used to create seals and gaskets in various construction applications.

- Rail and Track Pads: Rubber extrusions are used as rail and track pads to reduce vibration and noise in railway construction.

- Protective Bumpers: Rubber extrusions are used as protective bumpers on equipment and machinery to absorb impact and prevent damage.

- Gutter Seals: Rubber extrusions are used as seals for gutter systems, preventing water leaks and directing water flow away from the building.

- Soundproofing Seals: Used in soundproofing applications to create acoustic seals around doors, windows, and other openings.

Rubber extrusion also allows for the creation of complex shapes and designs, catering to specific construction requirements. Furthermore, it provides excellent flexibility and elasticity, facilitating easy installation and reducing the need for frequent maintenance. With Clifton Rubber, our extrusion capabilities enhance construction efficiency, energy efficiency, and structural integrity, contributing to safer and more sustainable buildings.

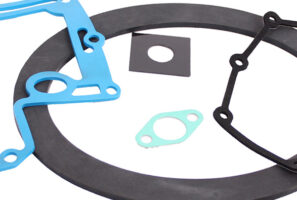

Rubber Sheet Conversion For For The Construction Industry

At Clifton Rubber, we specialise in transforming rubber sheeting into tailor-made rubber gaskets, seals, and other non-metallic components such as washers, insulations, and sheeting.

Our rubber gaskets are crafted according to the customer’s specifications, offering a wide range of shapes and sizes to accommodate even the most unique requirements.

Rubber Sheeting is used in construction for applications such as:

- Roofing Membranes

- Weather Stripping

- Vibration Isolation

- Flooring and Mats

- Soundproofing

- Gaskets and Seals

- Electrical Insulation and Damp Proofing

- Protective Pads and Bumpers

Rubber sheets offer a wide range of applications in construction, contributing to the waterproofing, insulation, protection, and comfort of buildings and structures. Their ease of use and adaptability make them valuable materials in various construction projects.

While many of our rubber gasket products are cut from rubber sheet materials, we also have the capability to manufacture fully moulded gaskets and seals. Additionally, we provide the option of supplying parts with a self-adhesive backing, available in custom lengths, widths, and thicknesses.

Precision Engineering For The Construction Industry

By employing advanced manufacturing techniques, rubber products can be precisely engineered to meet the specific requirements of construction projects.

This level of precision ensures optimal fit, functionality, and performance of rubber components such as seals, gaskets, and vibration dampers. The accurate dimensions and tight tolerances achieved through precision engineering result in improved sealing effectiveness, reduced energy loss, and enhanced durability.

Additionally, precision-engineered rubber products contribute to noise reduction, vibration isolation, and structural stability, thereby enhancing comfort and safety in buildings and infrastructure. Precision engineering ensures that construction projects are executed with high levels of accuracy, leading to improved safety, reduced wastage, increased productivity, and enhanced project outcomes.

Clifton Rubber offers a range of Bespoke Rubber Components for various industry sectors, including construction. Our custom made products for your industry include:

We also provide Custom Polyurethane solutions tailored to specific industry needs.