Rubber Covering

- Trusted by many leading manufacturers in various global industries

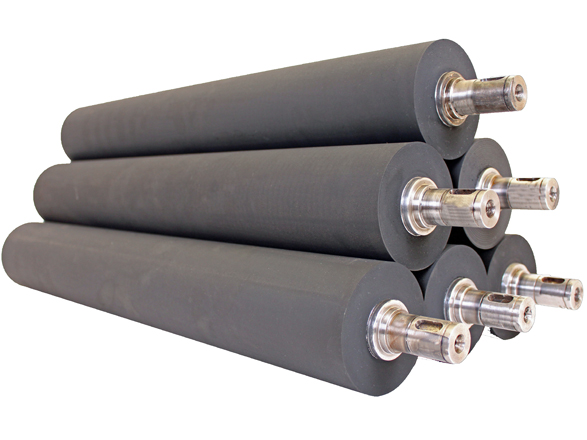

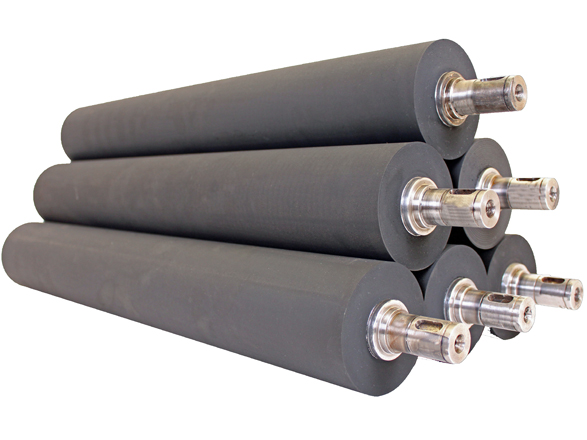

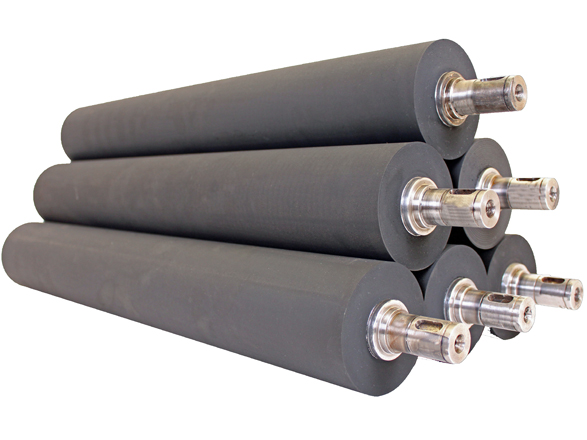

- We can strip and rubber cover existing items including rollers & wheels

- Competitive pricing and quick turnaround times

- Our in-house engineering team can fabricate complete new drums and hubs for rubber covering

- We can arrange collection and delivery of your existing rollers and wheels

Industrial Rubber Coating For Rollers & Wheels

Our rubber covering capabilities allow us to manufacture from new or strip and recover a wide range items. These often fall into the two main categories below. However, with over 50 years of expertise we are always on hand to discuss any rubber covering project, no matter how simple or complex.

Custom Industrial Rubber Coating For Rollers & Wheels Services

We are one of the UK’s leading experts in rubber covering and lining.

At Clifton Rubber we have over 50 years of experience in covering rollers and wheels in both rubber and polyurethane materials, supplying a wide range of customers in various industries including agriculture, transport, vintage machinery, food processing, textiles and quarrying.

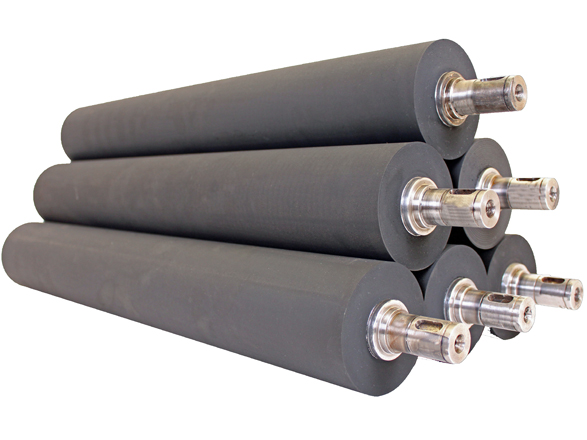

We can cover new rollers free issued to us, strip and re-cover existing rollers or manufacture complete rubber covered rollers including the fabricated steel or aluminum drum and shaft.

We are with you every step of the way

Our History and Expertise

We have an extensive range of rubber covering equipment including one of the largest diameter autoclaves in the UK. This capacity means we can cover items from small precision rollers for the print industry up to large 3m diameter conveyor drums used in the mining and quarrying industry. We offer short lead times as standard and can cater for break down situations where rollers need to be turned around quickly.

Our expert team have accumulated many years’ experience in rubber covering rollers and wheels and can advise on any issues or queries including material specifications or end use applications.

To maintain a quality product and service we put quality at the heart of our processes. Our quality management system is therefore certified to ISO9001.

The Rubber Covering Process

We offer a range of covering options. We can cover items free issued to us, strip and re-cover existing parts or manufacture complete items including the fabricated steel or aluminum drums and shafts.

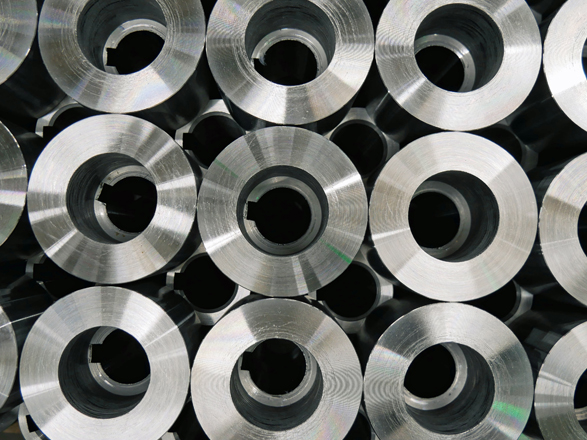

Our engineering unit has a highly skilled workforce and advanced CNC milling, turning and fabricating equipment offering the capability to manufacture high quality components for rubber covering.

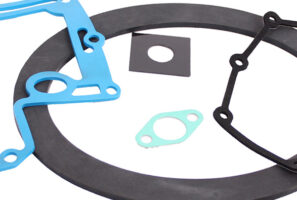

Rubber Covered Parts

We cover various items for a range of applications in different industries. Typical items are:

Materials

For our customer’s benefit we can offer rubber coverings manufactured from common commercially available rubber and in a wide spectrum of colours and hardness.

We stock materials formulated for high and low temperature, food quality (FDA approved), anti-static and flame retardant applications.

Our stock materials include:

- Ebonite

- SBR

- Natural Rubber (NR)

- Neoprene

- Nitrile

- EPDM

- Hypalon

- Silicone

- Polyurethane

Find out more about our other Capabilities

Companies We’ve Worked With

0

1

2

3

4

5

Industries We Work In

We manufacture rubber covered items for a range of applications in various industries. Some examples are listed below:

-

Aerospace

-

Agriculture

-

Automotive

-

Buildings & Construction

-

Defence

-

Electronic Equipment

-

Food & Drink Processing

-

Manufacturing

-

Marine & Maritime

-

Material Handling

-

Medical Equipment

-

Mining & Quarrying

-

Oil & Gas

-

Paper & Packaging

-

Recycling Equipment

-

Renewables & Power

-

Sport & Leisure

-

Textiles & Clothing

-

Transport

-

Vintage Machinery

-

Water & Sewage

Testimonials

-

“There are a lot of rubber rollers in our food processing plant and Clifton Rubber have always provided a great refurbishment service when our rollers need repairing. We get our rollers back quickly and they are always great quality.”

Brad, Maintenance Engineer, Food Processor

-

“Excellent service which is unusual in this day and age. The polyurethane screening stars do the job great, very very pleased.”

Richard, Owner, Screener Manufacturer

-

“Really pleased we found Clifton rubber, their technical team really helped us in the early stages of our project and now they produce our parts which we know will be top quality every time.”

Sophie, Purchasing Manager

-

“Just to let you know that our new ditch matting that we purchased from you is spot on. Used all through this busy season, really pleased with it.”

Ken, Fairford Bowling Club

-

“Since Clifton Rubber has taken over the re-covering of these gripper pads the customer has had no premature failures and the products have a much longer lifespan.”

Tom, Manufacturing Company

Rubber Covering FAQs

-

Are rubber coverings heavy duty?

We cover products in a range of thicknesses depending on the end application of the rubber roller. For example, natural rubber has strong physical characteristics such as high abrasion and tear resistance, good mechanical grip, and excellent flexibility. It is therefore suitable for most industrial applications.

-

What applications can rubber coverings be used for?

Rubber Coverings are used in a wide range of applications. Typical projects carried out by Clifton Rubber include:

- Conveyor Drive and Idlers

- Transfer

- Materials Handling

- Agriculture

- Laminating

- Squeegee

- Solid Tyre Wheels

- Food Processing

-

What is the process of rubber coverings?

To find out all about the rubber covering process read more HERE

-

Can I have my roller covered in any colour?

For our customer’s benefit we can offer rubber rollers manufactured from common commercially available rubber and in a wide spectrum of colours and hardness.

-

Which type of rubber is used as lining material?

We stock materials formulated for high and low temperature, food quality (FDA approved), anti-static and flame retardant applications.

Our stock materials include:

- Ebonite

- SBR

- Natural Rubber (NR)

- Neoprene

- Nitrile

- EPDM

- Hypalon

- Silicone

- Polyurethane

Vintage Fire Engine tyres for the Vintage Machinery Industry

Vintage Fire Engine tyres for the Vintage Machinery Industry Vintage fire engines are iconic symbols of early emergency response—often beautifully restored and proudly displayed at heritage shows, museums, and parades. Whether horse-drawn or early motorised versions, restoring these classic vehicles requires components that honour traditional craftsmanship while delivering dependable modern performance. At Clifton Rubber, we…

READ MORE

Living Van Tyres for the Vintage Machinery Industry

Living Van Tyres for the Vintage Machinery Industry Living vans are an iconic part of Britain’s steam-powered heritage, serving as mobile homes for workers during the steam era and often accompanying traction engines at events today. Whether used for display or as part of a working setup, restoring these support vehicles calls for historically accurate…

READ MORE

Traction Engine Tyres for the Vintage Machinery Industry

Traction Engine Tyres for the Vintage Machinery Industry Vintage machinery restoration requires a precise balance between historical authenticity and modern functionality. At Clifton Rubber, we specialise in manufacturing Traction Engine solid tyres that honour the legacy of historic steam and traction engines while incorporating the durability and reliability of modern rubber technology. Whether you are…

READ MORE

Moulded Strakes for the Vintage Machinery Industry

Moulded Strakes for the Vintage Machinery Industry When it comes to restoring vintage traction engines and agricultural vehicles, attention to detail is everything. Moulded Strakes, originally used as traction aids on metal wheels, are a crucial component of many historical machines. At Clifton Rubber, we manufacture robust, reliable rubber moulded strakes that preserve the character…

READ MORE

Chute Liners for the Mining & Quarrying Industry

Chute Liners for the Mining & Quarrying Industry In mining and quarrying operations, material transfer points are exposed to high levels of abrasion, impact, and wear. To protect these critical zones and extend the service life of equipment, Chute Liners play a vital role. At Clifton Rubber, we manufacture heavy-duty rubber and polyurethane chute liners…

READ MORE

Conveyor Rollers for the Mining & Quarrying Industry

Conveyor Rollers for the Mining & Quarrying Industry Conveyor systems are the backbone of material handling in the mining and quarrying sectors. Whether transporting crushed rock, ores, or aggregate over long distances, conveyor rollers must endure high loads, abrasive materials, and harsh environmental conditions. At Clifton Rubber, we produce high-quality conveyor rollers specifically engineered for…

READ MORE

Ceramic & Rubber Rollers for the Mining & Quarrying Industry

Ceramic & Rubber Rollers for the Mining & Quarrying Industry In the rugged world of mining and quarrying, reliable material handling equipment is essential for efficient operations. Rollers used in conveying, crushing, and screening systems are exposed to extreme wear, corrosion, and high-impact loads. At Clifton Rubber, we manufacture Ceramic & Rubber Rollers that combine…

READ MORE

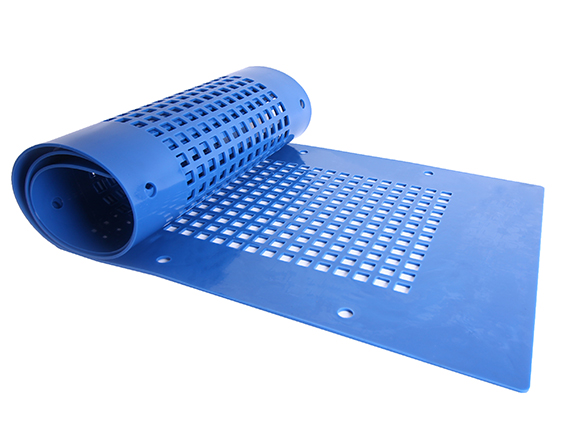

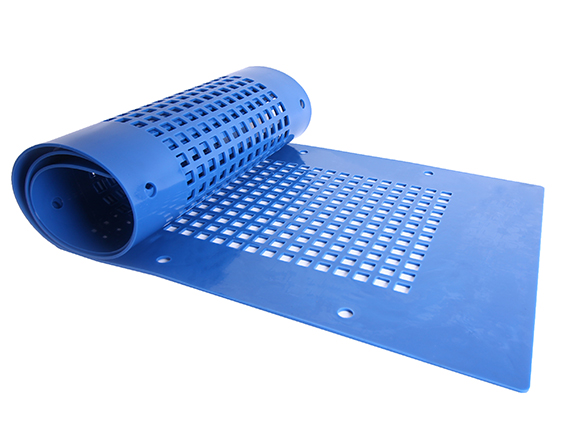

Polyurethane Screen Mats for the Mining & Quarrying Industry

Polyurethane Screen Mats for the Mining & Quarrying Industry In the demanding environments of mining and quarrying, material screening plays a critical role in separating valuable minerals and aggregates. The efficiency and longevity of your screening equipment depend heavily on the quality of your screen mats. At Clifton Rubber, we manufacture Polyurethane Screen Mats that…

READ MORE

Conveyor Rollers for the Material Handling Industry

Conveyor Rollers for the Material Handling Industry In the material handling industry, efficient product movement is essential for productivity. Whether moving parcels in a distribution centre or heavy loads in a bulk handling facility, conveyor rollers form the backbone of many operations. Poor-quality rollers can lead to frequent breakdowns, belt misalignment, and costly downtime. At…

READ MORE

Conveyor Idler & Return Discs for the Material Handling Industry

Conveyor Idler & Return Discs for the Material Handling Industry In the material handling industry, conveyor systems are at the heart of moving goods efficiently. Over time, continuous belt contact, abrasive materials, and heavy loads can cause excessive wear to conveyor rollers and belts. Conveyor idlers and return discs play a vital role in protecting…

READ MORE

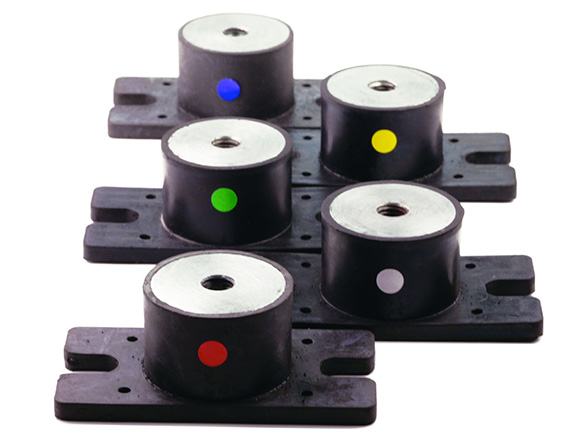

Vibration Isolation Mounts for the Material Handling Industry

Vibration Isolation Mounts for the Material Handling Industry In the material handling industry, machinery often operates under heavy loads and high speeds, creating vibrations that can cause equipment wear, noise, and reduced performance. Vibration isolation mounts are essential components designed to absorb and dampen these vibrations, protecting both the equipment and the operator. At Clifton…

READ MORE

Rubber Grip Pads for the Material Handling Industry

Rubber Grip Pads for the Material Handling Industry In the fast-paced material handling sector, ensuring safe, secure, and efficient load movement is essential. Rubber Grip Pads are a critical component for equipment such as forklifts, clamp trucks, and handling attachments, offering superior grip, load protection, and reduced wear. At Clifton Rubber, we manufacture durable, high-performance…

READ MORE

Suspension Bushes for the Transport And Logistics Industry

High-Quality Suspension Bushes for the Transport & Logistics Industry Suspension bushes are critical components in commercial vehicles, reducing vibrations, improving ride stability, and enhancing overall durability. Clifton Rubber manufactures high-quality suspension bushes designed for heavy-duty transport applications, ensuring longevity and reliability in demanding conditions. Custom Suspension Bush Manufacturer & Supplier for the Transport & Logistics…

READ MORE

Screening Planks for the Waste And Recycling Industry

High-Performance Screening Planks for the Waste And Recycling Industry In the fast-paced and demanding world of waste and recycling, equipment efficiency and durability are vital. Clifton Rubber manufactures robust screening planks that support effective material separation, increased throughput, and reduced equipment wear. Designed for a range of screening machinery, our rubber screening planks help waste…

READ MORE

Rubber Fenders for the Transport And Logistics Industry

High-Quality Rubber Fenders for the Transport & Logistics Industry Rubber fenders are essential for safeguarding docks, ports, and vessels by absorbing impact forces during berthing. Clifton Rubber manufactures high-quality rubber fenders designed for durability, impact resistance, and long-term performance, ensuring maximum protection for maritime and logistics operations. Custom Rubber Fender Manufacturer & Supplier for the…

READ MORE

Rail Track Pads for the Transport And Logistics Industry

High-Quality Rail Track Pads for the Transport & Logistics Industry Rail track pads are essential components in railway systems, providing critical cushioning and vibration reduction between the rail and sleeper. Clifton Rubber manufactures high-quality rail track pads designed for durability, noise reduction, and enhanced track longevity, ensuring smooth and efficient railway operations. Custom Rail Track…

READ MORE

Loading Bay Buffers For The Transport And Logistics Industry

High-Quality Loading Bay Buffers For The Transport & Logistics Industry Loading bay buffers play a crucial role in protecting warehouses, distribution centres, and commercial vehicles from impact damage. Clifton Rubber manufactures high-quality, durable loading bay buffers designed to absorb impact forces, reduce maintenance costs, and improve safety in transport and logistics operations. Custom Loading Bay…

READ MORE

Flip Flow Screen Mats for the Waste And Recycling Industry

Flip Flow Screen Mats for the Recycling Industry In the recycling industry, where materials are often wet, sticky, or irregular in size, traditional screening systems can struggle. Clifton Rubber’s flip flow screen mats offer a powerful solution—flexible, hard-wearing rubber mats that vibrate dynamically to separate even the most challenging materials. Engineered for efficiency and durability,…

READ MORE

Screening Modules for the Waste And Recycling Industry

Screening Modules for the Waste And Recycling Industry Recycling facilities demand tough, reliable equipment that can perform consistently in challenging environments. At Clifton Rubber, we design and manufacture high-performance rubber screening modules that deliver excellent separation, durability, and ease of maintenance. Whether processing municipal waste, aggregates, plastics, or compost, our screening modules are engineered to…

READ MORE

Trommel Wheels for the Waste And Recycling Industry

Trommel Wheels for the Waste And Recycling Industry In the fast-paced and abrasive world of recycling, equipment needs to perform reliably under pressure. Trommel screens—used for sorting and sizing recyclable materials—depend on durable components to keep operations moving efficiently. Clifton Rubber’s trommel wheels are purpose-built to meet these demands, offering a high-performance solution that ensures…

READ MORE

Coating & Laminating Rollers for the Paper & Packaging Industry

Coating & Laminating Rollers for the Paper & Packaging Industry Coating and laminating rollers are indispensable tools in the paper and packaging industry, enabling manufacturers to achieve high-quality finishes and efficient production. Clifton Rubber specialises in crafting durable, high-performance rollers that meet the specific demands of coating and laminating applications. Custom Coating & Laminating Roller…

READ MOREInk Transfer Rollers for the Paper & Packaging Industry

Ink Transfer Rollers for the Paper & Packaging Industry Ink transfer rollers play a pivotal role in the printing industry, ensuring accurate and consistent ink distribution for high-quality results. Clifton Rubber specialises in producing durable, high-performance ink transfer rollers that meet the demands of modern printing technologies. Custom Ink Transfer Roller Manufacturer & Supplier for…

READ MORE

Press Rollers for the Paper & Packaging Industry

Press Rollers for the Paper & Packaging Industry Press rollers are critical components in the paper and packaging industry, facilitating smooth and efficient production processes. Clifton Rubber specialises in manufacturing high-quality press rollers that deliver durability, precision, and superior performance in demanding applications. Custom Press Roller Manufacturer & Supplier for the Paper & Packaging Industry…

READ MORE

Embossing Rollers for the Paper & Packaging Industry

Embossing Rollers for the Paper & Packaging Industry Embossing rollers are indispensable tools in the paper and packaging industry, enabling manufacturers to achieve high-quality finishes and efficient production. Clifton Rubber specialises in crafting durable, high-performance rollers that meet the specific demands of embossing applications. Custom Embossing Roller Manufacturer & Supplier for the Paper & Packaging…

READ MORE

Squeeze Rollers for the Textiles & Clothing Industry

Squeeze Rollers for the Textiles & Clothing Industry Squeeze rollers are essential components in textile processing, helping to remove excess water, chemicals, and other liquids from fabrics during various production stages. Clifton Rubber manufactures premium squeeze rollers designed for durability, precision, and efficiency, ensuring optimal moisture control and fabric treatment. What Are Squeeze Rollers? Squeeze…

READ MORE

Sizing Rollers for the Textiles & Clothing Industry

Sizing Rollers for the Textiles & Clothing Industry Sizing rollers play a crucial role in textile manufacturing, ensuring fabric strength, smoothness, and uniformity during production. At Clifton Rubber, we specialise in manufacturing precision-engineered sizing rollers that enhance efficiency and product quality in the textiles and clothing industry. Custom Sizing Roller Manufacturer & Supplier for the…

READ MORE

Guide Rollers for the Textiles & Clothing Industry

Guide Rollers for the Textiles & Clothing Industry Guide rollers play a crucial role in textile manufacturing by ensuring proper fabric alignment and smooth movement through production lines. Clifton Rubber manufactures durable and high-performance guide rollers that help optimise efficiency, reduce fabric distortion, and improve overall textile quality. Custom Guide Roller Manufacturer & Supplier for…

READ MOREBleaching Rollers for the Textiles & Clothing Industry

Bleaching Rollers for the Textiles & Clothing Industry Bleaching rollers play a critical role in textile manufacturing by ensuring even application of bleaching agents to fabrics, improving whiteness and fabric quality. Clifton Rubber specialises in manufacturing premium bleaching rollers that provide durability, precision, and efficiency for textile processing. Custom Bleaching Roller Manufacturer & Supplier for…

READ MORE

Riser Clamps for the Renewables & Power Industry

Riser Clamps for the Renewables & Power Industry Riser clamps are essential components in the renewables and power industry, ensuring secure and stable support for pipes and cables in demanding environments. Clifton Rubber specialises in designing and manufacturing premium riser clamps tailored for renewable energy and power infrastructure projects. Custom Riser Clamps Manufacturer & Supplier…

READ MORE

Piggyback Clamps and Saddles for the Renewables & Power Industry

Piggyback Clamps and Saddles for the Renewables & Power Industry Piggyback clamps and saddles play a crucial role in the renewables and power industry, ensuring the secure and efficient installation of cables and pipes. Clifton Rubber provides high-quality solutions designed to meet the rigorous demands of renewable energy projects. Custom Piggyback Clamp and Saddle Manufacturer…

READ MORE

Pipe Laying Rollers for the Renewables & Power Industry

Pipe Laying Rollers for the Renewables & Power Industry Pipe laying rollers are critical tools in the renewables and power industry, ensuring the safe and efficient handling of cables and pipes during installation. Clifton Rubber specialises in manufacturing high-quality vertical, horizontal, and diablo pipe laying rollers, designed to meet the demanding requirements of the sector.…

READ MORE

Cable and Pipe Protectors for the Renewables & Power Industry

Cable and Pipe Protectors for the Renewables & Power Industry Cable and pipe protectors are essential in the renewables and power industry, ensuring the safety and longevity of critical infrastructure. Clifton Rubber specialises in manufacturing high-quality protectors that shield cables and pipes from damage during installation and operation in demanding environments. Custom Cable and Pipe…

READ MORE

Piggyback Clamps and Saddles for the Oil and Gas Industry

Piggyback Clamps and Saddles for the Oil and Gas Industry In the oil and gas industry, ensuring the secure installation of pipelines is critical. Clifton Rubber’s high-performance piggyback clamps and saddles are designed to meet these demands, providing robust solutions for pipeline attachment and stabilisation. Our clamps and saddles are manufactured to the highest standards,…

READ MORE

Cable and Pipe Protectors for the Oil and Gas Industry

Cable and Pipe Protectors for the Oil and Gas Industry In the demanding environments of the oil and gas industry, protecting cables and pipes is critical to ensure operational efficiency and safety. Clifton Rubber’s high-quality cable and pipe protectors are designed to shield essential infrastructure from impact, abrasion, and environmental damage. Our protectors are trusted…

READ MORE

Cable Sheath Linings for the Oil and Gas Industry

Cable Sheath Linings for the Oil and Gas Industry Cables are critical components in the oil and gas industry, carrying power, signals, and data across vast and often challenging environments. Clifton Rubber’s cable sheath linings provide an essential layer of protection, ensuring optimal cable performance and longevity. Our linings are designed to withstand extreme conditions,…

READ MORE

Pipe Laying Rollers for the Oil and Gas Industry

Pipe-Laying Rollers for the Oil and Gas Industry In the oil and gas industry, where precision and reliability are paramount, pipe-laying rollers play a critical role. Clifton Rubber offers high-quality vertical, horizontal, and diablo pipe-laying rollers, designed to facilitate efficient and safe pipe installation in offshore and onshore projects. Our rollers are engineered to withstand…

READ MORE

Rubber Buckle Covers for the Defence Industry

Rubber Buckle Covers for the Defence Industry In the demanding environments of the defence industry, protecting essential fastening systems is crucial. Rubber buckle covers from Clifton Rubber provide robust protection for straps, harnesses, and fastening systems, ensuring their functionality and durability during critical operations. Engineered with precision, our rubber buckle covers are built to withstand…

READ MORE

Aerial Protectors for the Defence Industry

Aerial Protectors for the Defence Industry In the defence industry, where reliability and precision are critical, protecting sensitive equipment like communication aerials is a top priority. Clifton Rubber offers high-quality aerial protectors designed to shield military vehicle antennas from damage during operation. These protectors ensure consistent communication, reduced maintenance costs, and enhanced operational efficiency in…

READ MORE

Tank Wheels for the Defence Industry

Tank Wheels for the Defence Industry Tank wheels are critical to the operational success of military vehicles, providing the strength, durability, and reliability needed for extreme conditions. At Clifton Rubber, we specialise in designing and manufacturing tank wheels that meet the rigorous demands of defence applications. Our wheels ensure consistent performance, extended lifespan, and superior…

READ MORE

Anti-Vibration Mounts for the Defence Industry

Anti-Vibration Mounts for the Defence Industry In the defence industry, where precision and reliability are paramount, controlling vibrations is critical to maintaining the integrity and performance of equipment. Clifton Rubber manufactures high-quality anti-vibration mounts tailored to meet the demanding requirements of military and ddefenceapplications. These mounts ensure stability, extend equipment life, and optimise operational efficiency…

READ MORE

Heavy-Duty Bucket Bump Stops for Construction Equipment

Heavy-Duty Bucket Bump Stops for Construction Equipment Bucket bump stops are essential components in heavy machinery used in the construction industry. At Clifton Rubber, we specialise in manufacturing robust rubber bump stops designed to protect both machinery and materials during operation. Our bump stops are engineered to withstand the harsh conditions of construction environments, providing…

READ MORE

Durable Dock Buffers for the Construction Industry

Durable Dock Buffers for the Construction Industry Dock buffers are essential for protecting loading bays and vehicles during the loading and unloading process, ensuring both safety and efficiency. At Clifton Rubber, we manufacture high-quality rubber dock buffers designed to withstand heavy impact and provide long-lasting protection. Our products are engineered to handle the rigorous demands…

READ MORE

Efficient Brick Grabs for the Construction Industry

Efficient Brick Grabs for the Construction Industry Brick grabs are specialised lifting devices designed to securely grip and transport bricks. They are typically used with cranes or forklifts and can accommodate various sizes and weights of bricks. Clifton Rubber offers a range of brick grabs tailored to meet the diverse needs of the construction industry,…

READ MORE

Durable Rubber Window Seals for the Construction Industry

Durable Rubber Window Seals for the Construction Industry Rubber window seals play a vital role in ensuring that buildings are energy-efficient, well-insulated, and protected from external elements. At Clifton Rubber, we specialise in producing top-tier rubber window seals that cater to the diverse needs of the construction industry. Our seals are engineered for durability, performance,…

READ MORE

Durable Door Seals for the Automotive Industry

Durable Door Seals for the Automotive Industry Door seals are vital components in vehicles, providing a secure fit between the door and the vehicle’s frame. They are designed to prevent water, air, and noise from entering the cabin, enhancing comfort and driving experience. At Clifton Rubber, we manufacture high-quality door seals that meet the rigorous…

READ MORE

Engine Mount Products for the Automotive Industry

Engine Mount Products for the Automotive Industry Engine mounts are essential components in any vehicle, playing a crucial role in reducing engine vibration and ensuring engine stability. At Clifton Rubber, we specialise in producing high-quality engine mounts that meet the demands of modern vehicles, delivering improved performance, comfort, and durability. Custom Engine Mounts Manufacturer &…

READ MORE

Buffer Products for the Automotive Industry

Buffer Products for the Automotive Industry Buffers play a critical role in the automotive industry by absorbing shocks, reducing vibration, and protecting vital components from damage. At Clifton Rubber, we specialise in designing and manufacturing top-tier buffers that enhance vehicle performance and durability, ensuring safety and longevity for both vehicles and their components. Custom Buffer…

READ MORE

Rubber Hose Products for the Automotive Industry

Rubber Hose Products for the Automotive Industry Rubber hoses play a critical role in the automotive sector, ensuring the efficient transport of fluids like fuel, coolant, and brake fluid throughout vehicles. At Clifton Rubber, we specialise in producing durable, reliable, and versatile rubber hoses designed to meet the exacting standards of the automotive industry. Bespoke…

READ MORE

Track Wheels Recovered for Agricultural Customer

We were recently approached by a customer in the Agricultural Industry to re-cover his existing John Deere Track Wheels.

READ MORE

A Rubber Diaphragm for a Leading Pump Manufacturer

We were approached by a leading pump OEM to manufacture an advanced rubber diaphragm for their new range of diaphragm pumps.

READ MORE

Wheel Covering Project for Vintage Fire Engine

At Clifton Rubber we cover all types of wheels, some of which can be found on vintage machinery.

READ MORE

Quality Wins a New Rubber Moulding Customer

We were recently approached by a long-established UK manufacturing company to produce a rubber collet which was bespoke to their needs.

READ MORE

Bespoke Polyurethane Manufacturing Project

We were recently approached by a company enquiring if we could manufacture a very specialised, bespoke polyurethane product for them.

READ MORE

Enlightening Polyurethane Moulding Solution

We have recently completed a new polyurethane moulding project for a leading British manufacturer of external lighting.

READ MORE

Polyurethane Solution for Lifting Equipment

We have just completed a successful polyurethane moulding project for a Maintenance company specialising in Lifting Equipment.

READ MORE

Rubber Roller Project Provides Subsea Solution

Always striving to offer bespoke solutions to meet specific customer requirements, in whatever industry, we recently worked on a rubber roller covering project for a company in the Offshore industry.

READ MORE

Bowls Club Reflects on Ditch Liners’ Quality

Bowling Club Reflects on Ditch Liners’ Quality and Longevity after 3 Years of Use

READ MORE

PU Moulding Project for Hospitality Sector

We have recently successfully completed an interesting project for a new consumer products company. The customer required a bespoke polyurethane drip tray moulding, which would form part of a new piece of high-end bar equipment.

READ MORE

Customer Saves with New Rubber Covered Gripper Pad

Unhappy with the quality of rubber gripper pads used on their machines, a new customer approached us to find a solution to limit the downtime they were experiencing on their machines.

READ MORE

Water Valve Linining Project

rubber moulding project pic Bespoke Rubber Air Valve Lining Project Successfully Delivered to an Engineering Solutions Customer

READ MORE