Custom Transport Rubber Component Manufacturer & Supplier

Clifton Rubber is a leading supplier to the UK and European automotive and transport industries. We manufacture various bespoke rubber components for several leading Original Equipment Manufacturers as both a tier 1 and tier 2 supplier.

Clifton Rubber also manufactures and supplies a range of standard own-brand products for general use in the transport industry including Tipper Blocks, Buffer Blocks, Dock Buffers and Extrusions, details of which are listed below.

From moulding processes to precision engineering, discover how these components play an essential role in enhancing the transport industry.

To find out more about each of our Capabilities in the Transport Industry…

Read MoreCustom Transport Rubber Component Manufacturing Services

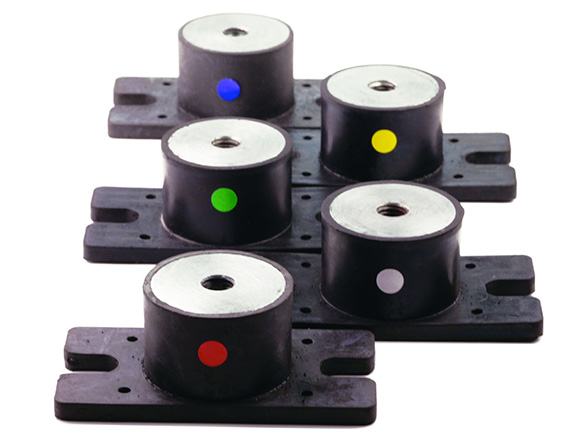

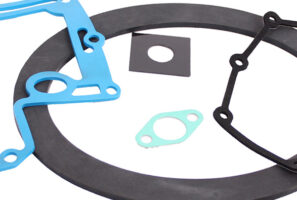

Rubber Moulding For The Transport Industry

Rubber Moulding enables the production of custom rubber components that enhance vehicle performance and safety. From gaskets and seals to suspension bushings and engine mounts, rubber moulding ensures precise and durable parts. These components help reduce vibration and noise, leading to smoother rides and prolonged vehicle lifespan.

Rubber moulded components used in the transport industry include:

- Gaskets and Seals: Rubber gaskets and seals prevent the leakage of fluids, gases, and air used in engines, doors, windows, etc.

- Wheels and Tyres: Clearly used on most vehicles.

- O-Rings: O-rings are used in hydraulic systems and engines to seal and fluid leakage.

- Hoses and Tubing: Rubber hoses and tubing are used in various fluid systems within vehicles, including coolant hoses, fuel hoses, and brake lines.

- Extruded Rubber Profiles: We offer a range of standard rubber extrusions including D fenders, squashed D sections, double and single tailgate seals, trapezium chimneys and rubber jeeting among other products.

- Drive Belts: Rubber drive belts, such as serpentine belts, are used to transmit power from the engine to various vehicle components.

Rubber Tipper Body Pads:: Clifton Rubber’s tipper body pads set the industry standard for tipper chassis protection

Rubber’s versatility and ability to withstand harsh conditions make it ideal for transportation applications.

Polyurethane Moulding For The Transport Industry

Polyurethane moulding offers significant benefits to the transport industry, revolutionising the manufacturing of vehicle components. With its exceptional versatility, it allows the creation of complex, lightweight, and durable parts. Polyurethane bumpers, seals, and interior components enhance safety and comfort. Its superior resilience and resistance to wear and tear result in longer-lasting parts, reducing maintenance and replacement costs.

Additionally, polyurethane’s ability to dampen vibrations and noise contributes to a smoother, quieter ride. The material’s low weight-to-strength ratio boosts fuel efficiency and reduces carbon emissions.

Here are some common polyurethane moulded components used in the transport industry:

Bump Stops: Polyurethane bump stops are typically used as a bucket bump stop on earthmoving equipment.

Loading Bay Buffers: Our Pu loading bay buffers are manufactured from high quality polyurethane for extra long life and durability .

Roller and Bumper Stops: Polyurethane rollers and bumpers are used in various transport applications, including conveyor systems, loading docks, and truck bumpers.

- Forklift and Material Handling Equipment Components: Polyurethane is used in various components of forklifts and material handling equipment – tyres, and loading.

- Custom Parts: Polyurethane can be moulded into custom components.

- Extruded Rubber Profiles: We offer a range of standard PU extrusions including D fenders, squashed D sections, double and single tailgate seals, trapezium chimneys and rubber jeeting among other products.

Polyurethane’s versatility and strength make it an ideal material for the transport industry.

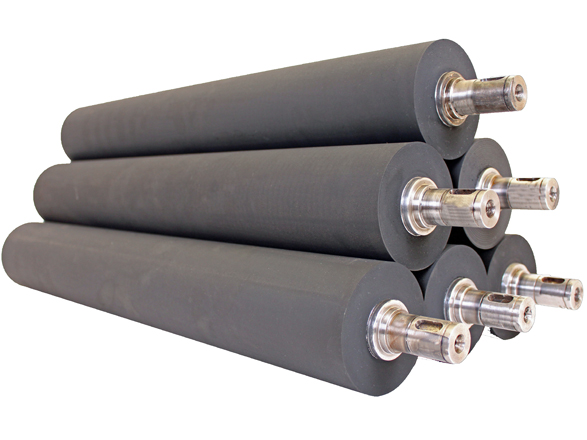

Rubber Covering including

- Rubber Rollers For The Transport Industry

- Rubber Wheels & Tyres The Transport Industry

Rubber covering offers invaluable benefits to the transport industry across various applications. One key advantage is its ability to provide enhanced grip and traction, making it ideal for vehicle tires and conveyor belts. This improved traction ensures safer driving conditions and efficient material handling in warehouses and logistics centers. Moreover, rubber covering protects critical surfaces from abrasion, impact, and corrosion, prolonging the lifespan of components.

Rubber covering, including rubber rollers, wheels, and tyres, brings significant advantages to the transport industry.

Rubber rollers provide exceptional traction and grip, facilitating the movement of heavy machinery and equipment with enhanced stability and control.

Rollers are used in various applications in the transport industry including:

- Rollers: Rubber and Polyurethane rollers are used in various parts of vehicles, including cars, trucks, buses, and trains.

- Vehicles: such as excavators, concrete mixers and dumper trucks

- Traction Rollers: Rubber rollers can be found in various parts of vehicles, including wheels and rollers for door mechanisms, window regulators, and belt tensioners. They provide friction and help with smooth movement.

- Transport Rollers for Materials Handling Equipment: Rubber-coated rollers are used on material handling equipment such as forklifts, pallet jacks, and dollies. They provide traction and reduce the risk of slippage when moving heavy loads.

Rubber wheels and tyres provide superior load-bearing capacity, ensuring smooth transportation of materials on various terrains. Their elasticity and resilience contribute to a comfortable ride and improved safety.

Rubber wheels and tyres are essential components of transportation systems and are used in various modes of transport:

- Cars

- Trucks and Commercial Vehicles

- Motorcycles and Bicycles

- Aircraft

- Trains

- Tractors

- Bicycles & Motorbikes

- On Ships

- On Construction Equipment

- Vintage Vehicles

Rubber tyres and wheels are used widely across the transport industry, ensuring safe, efficient, and comfortable travel for people and the transportation of goods.

Rubber covering solutions by Clifton Rubber offer excellent resistance to wear, tear, and chemicals, resulting in longer service life and reduced maintenance costs. Overall, rubber covering enhances productivity, efficiency, and safety.

Rubber Extrusion For The Transport Industry

Rubber extrusions cater to a wide range of applications in the construction industry.

Common uses of rubber extrusions in construction include:

- Weather Stripping: Rubber extrusions are used as weather stripping in vehicles.

- Vibration Dampeners: Used to dampen vibrations and reduce noise.

- Seals, O Rings and Gaskets: Rubber extrusions are used to create seals and gaskets in various construction applications.

- Rail and Track Pads: Rubber extrusions are used to seal joints in engines and other vehicle systems.

Protective Bumpers: Rubber extrusions are used as protective bumpers to absorb impact and prevent damage.

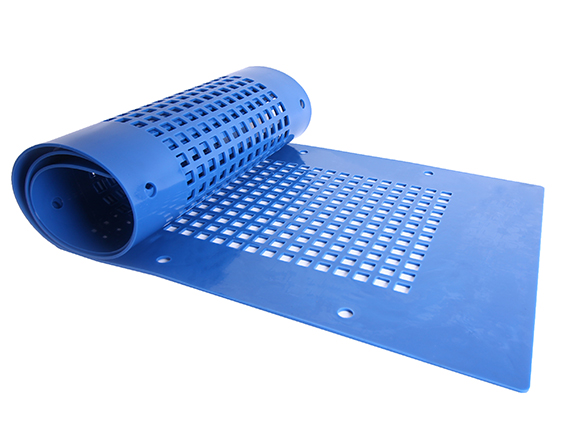

Rubber Sheet Conversion For The Transport Industry

Rubber sheet conversion allows rubber sheets to be custom-cut and moulded into various shapes, allowing for precise fabrication of vehicle components. From flooring mats to soundproofing materials, rubber sheets offer excellent anti-slip properties, enhancing safety within vehicles.

They also act as protective layers for cargo, shielding it from damage during transportation. Their resilience and weather resistance make them ideal for creating durable seals and gaskets, reducing the risk of leaks and ensuring optimal vehicle functioning. In summary, rubber sheet conversion contributes to improved safety, durability, and functionality in the transport sector.

Here are some ways rubber sheeting is used in the transport industry:

- Vehicle Flooring: Rubber sheeting is often used as flooring material in buses, trains, and other commercial vehicles as it is slip resistant, cushioned and prevents noise and vibration..

- Gaskets and Seals: Used to create gaskets and seals in engines, transmissions, and other vehicle components to prevent fluids leaks.

- Vibration Isolation: Can be used as isolators or dampers to reduce vibration and noise in various vehicle components.

- Bumper and Dock Protection: Used as a protective material on loading docks and bumpers to cushion the impact of vehicles during loading and unloading, reducing damage to both the vehicles and the infrastructure.

Railroad Applications: Rubber sheeting can be used in various railway applications.

Precision Engineering For The Transport Industry

Precision engineering plays a pivotal role in the transport industry. With its high-level accuracy and attention to detail, precision engineering ensures the production of intricately designed rubber and polyurethane components, optimising vehicle performance and safety.

Precise manufacturing processes lead to higher quality components meaning reduced wear and tear, extending the lifespan of transportation equipment and lowering maintenance costs.

Clifton Rubber offers a range of Bespoke Rubber Components for various industry sectors, including transport. Our custom made products for your industry include:

We also provide Custom Polyurethane solutions tailored to specific industry needs.