Rubber and Polyurethane Components Used For The Paper and Packaging Industry

Clifton Rubber supplies high quality rubber and polyurethane components to some of the leading companies in the paper and packaging industry.

We manufacture and supply a range of standard components and are also able to manufacture customer bespoke parts from rubber or polyurethane, using our in house manufacturing capabilities.

The paper and packaging industry relies heavily on durable and versatile materials to ensure efficient production and manufacturing. Two of the most vital materials used in this industry are rubber and polyurethane, both of which have properties that are ideal for manufacturing components which withstand the challenges of the industry.

From moulding processes to precision engineering, discover how these components play an essential role in enhancing the paper and packaging process.

To find out more about each of our Capabilities in the Paper & Packaging Industry…

Read MoreClifton Rubber Capabilities By Industry: Paper and Packaging

Rubber Moulding For The Paper and Packaging Industry

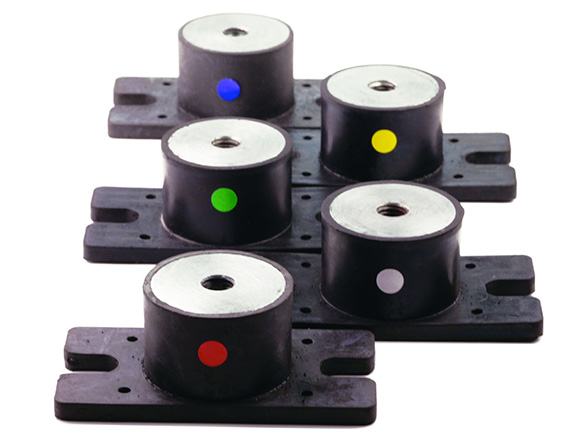

Rubber moulded components have various applications in the paper and packaging industry due to their unique properties such as flexibility, durability, and resistance to chemicals. Here are some common uses:

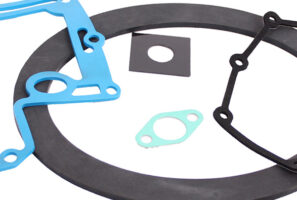

- Seals and Gaskets: Rubber seals and gaskets prevent leakage in packaging machinery. They provide effective sealing solutions for joints, valves, and other components.

- Suction Cups: Rubber suction cups are used in packaging machinery to handle and manipulate paper and packaging products during the packaging process. They create a vacuum seal to securely hold items in place.

- Vibration Dampers: Rubber components are utilised as vibration dampers in packaging machinery to reduce noise levels and minimise wear and tear caused by vibrations.

- Shock Absorbers: Rubber shock absorbers protect delicate equipment and materials from damage during transportation and handling processes. They are crucial for maintaining the integrity of packaged goods and preventing product damage.

- Anti-Skid Pads: Rubber pads with anti-skid properties are used on packaging equipment and storage surfaces to prevent slipping and shifting of paper and packaging materials. They enhance safety and stability in the workplace.

- Bumpers and Buffers: Rubber bumpers and buffers are employed to cushion impacts and prevent damage to machinery and materials during the packaging process. They absorb shocks and protect equipment from wear and tear.

Rubber moulded products play a crucial role in enhancing the efficiency, reliability, and safety of machinery and processes within the paper and packaging industry.

Polyurethane Moulding For The Paper and Packaging Industry

Polyurethane moulded components are lightweight, durable and resistant to wear and tear, heat and chemicals.

They are widely used in the industry but typically uses include:

- Scraper Blades: Polyurethane scraper blades are used in printing and coating equipment to remove excess ink or coatings from rollers or other surfaces.

- Wheels and Casters: Polyurethane wheels and casters are used in material handling equipment such as carts, pallets, and conveyors within the paper and packaging industry. They offer superior load-bearing capacity, impact resistance, and durability compared to traditional rubber or plastic wheels.

- Seals, gaskets, bumpers: components designed to enhance the performance and longevity of equipment.

- Foam Packaging Inserts: Polyurethane foam is often used as packaging material to protect fragile items during shipping and handling. Moulded polyurethane foam inserts provide cushioning and shock absorption, reducing the risk of damage to packaged goods.

- Impact Pads and Bumpers: Polyurethane impact pads and bumpers are employed to absorb shocks and prevent damage to machinery and materials during the packaging process. They offer excellent resilience and durability, making them ideal for high-impact applications.

- Dunnage and Spacer Blocks: Polyurethane dunnage and spacer blocks are used to separate and protect packaged goods during transit or storage. These moulded products help to prevent shifting and damage to sensitive items.

These are just a few examples of the polyurethane moulded products used in the paper and packaging industry. Their versatility and durability make them valuable components in various applications, contributing to improved efficiency and product protection.

Rubber Covering including

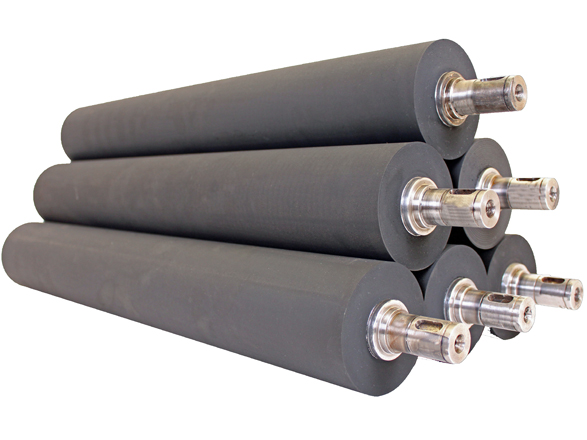

- Rubber Rollers For The Paper and Packaging Industry

- Rubber Wheels & Tyres For The Paper and Packaging Industry

Rubber coverings are utilised in the paper and packaging industries primarily for their ability to provide traction, protection, and surface properties necessary for the efficient operation of machinery and the quality of finished products. Rubber coverings are applied to rollers used in various paper processing and packaging machinery. These rubber coverings provide traction and grip to facilitate the movement of paper and packaging materials through the machinery. They also ensure uniform pressure distribution, which is essential for achieving consistent results in processes such as printing, laminating, and embossing.

Rubber Rollers For The Paper and Packaging Industry

Rubber rollers are widely used in the industry due to their ability to transport, sort, and process various materials effectively. Here are some common uses of rubber rollers in the paper and packaging industry:

- Printing: Rubber rollers are extensively used in printing presses for tasks such as ink application, plate transfer, and paper feeding.

- Laminating: In laminating processes, rubber rollers are employed to apply pressure and ensure proper adhesion between layers of materials such as paper, plastic films, or foils.

- Coating: Rubber rollers are used in coating machines to apply coatings or adhesives onto paper or packaging materials. The rollers evenly distribute the coating material across the substrate, ensuring uniform coverage and adhesion.

- Embossing and Debossing: Rubber rollers are utilised in embossing and debossing processes to create textured or raised patterns on paper and packaging materials. The rollers apply pressure to the substrate, pressing it against a corresponding patterned die or plate, resulting in the desired texture or design.

- Cutting and Creasing: Rubber rollers are integrated into cutting and creasing machinery to facilitate the cutting and shaping of paperboard or corrugated cardboard used in packaging. The rollers assist in feeding the material through the cutting or creasing mechanisms, ensuring precise and consistent results.

- Folding and Gluing: Rubber rollers play a role in folding and glueing processes in packaging production lines. They assist in guiding and folding paper or cardboard into the desired configurations and applying adhesive to bond the folds together, forming cartons, boxes, or other packaging containers.

- Wrapping and Sealing: Rubber rollers are used in wrapping and sealing machines to apply pressure and ensure secure sealing of packaging materials such as plastic films or shrink wrap around products. The rollers help to create tight seals and eliminate wrinkles or air pockets, ensuring the integrity of the packaging.

- Feeding and Transport: Rubber rollers are employed in various feeding and transport mechanisms throughout paper and packaging production lines. They help to guide and transport materials smoothly and efficiently through different stages of the manufacturing process, from printing to finishing and packaging.

Overall, rubber rollers are indispensable components in the paper and packaging industry, playing a vital role in ensuring the quality, efficiency, and functionality of various manufacturing processes.

Rubber Wheels & Tyres For The Paper and Packaging Industry

Rubber wheels and tyres are used in the paper and packaging industry in areas such as:

- Forklifts and Loaders

- Other Material Handling Equipment

- Conveyor Systems

- Printing and Labelling Machines

- Palletising Systems

The durability and versatility of rubber wheels and tyres make them suitable for various applications.

Rubber Extrusion For The Paper and Packaging Industry

Rubber extrusion stands as a significant asset to the industry.. Through this process, rubber can be transformed into various profiles, sheets, and tubes, paving the way for various applications across the industry.

- Sealing: Rubber extrusions are frequently used as sealing components in printing and packaging machinery. They provide effective sealing solutions for doors, hatches, chutes, and other openings to prevent the leakage of ink, fluids, or powders, ensuring clean and efficient operation of equipment.

- Edge Protectors: Rubber extrusions are used as edge protectors on printing plates, cutting dies, and other tools and equipment used in the printing and packaging processes.

- Gaskets: Rubber extrusions serve as gaskets in various printing and packaging equipment, providing a tight seal between mating surfaces to prevent leaks or contamination. They are commonly used in pumps, valves, containers, and other components where a reliable seal is essential for maintaining product quality and process efficiency.

- Guide Rails: Rubber extrusions are used as guide rails or bumpers on conveyor systems and packaging machinery to guide and control the movement of materials. They help to prevent product damage and misalignment while ensuring smooth and precise material handling throughout the production process.

- Anti-Vibration Mounts: Rubber extrusions serve as anti-vibration mounts or isolators in printing and packaging equipment to dampen vibrations and reduce noise levels. They help to protect sensitive components, improve print quality, and enhance operator comfort in high-speed and precision printing applications.

- Cushioning Pads: Rubber extrusions are employed as cushioning pads or buffers in packaging machinery to absorb shocks and impacts during the handling and packaging of products.

Rubber extrusions play a crucial role in the print and packaging industry by providing sealing, protection, cushioning, and vibration dampening solutions that contribute to the efficiency, quality, and safety of printing and packaging processes.

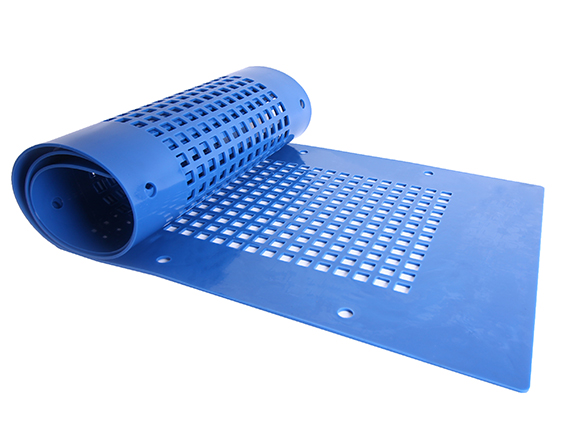

Rubber Sheet Conversion For The Paper and Packaging Industry

The rubber sheet conversion process allows for the transformation of rubber into flat sheets of various thicknesses and sizes. These sheets serve as the foundation for manufacturing new products, ranging from gaskets and seals to flooring and other applications.

Here are some applications of rubber sheet conversion in the paper and packaging industry:

- Gaskets and Seals

- Cushioning and Padding

- Anti-Skid Mats

- Vibration Dampening

- Mats and Flooring

Rubber sheets can be converted into custom components such as sleeves, strips, and pads, tailored to specific requirements in packaging machinery and processes. These components serve various functions, including sealing, cushioning, and insulation, enhancing the performance and reliability of equipment.

Precision Engineering For The Paper and Packaging Industry

recision Engineering ensures that paper and packaging machinery operates with high accuracy and consistency, leading to the production of high-quality paper products

Precision engineering enables the creation of advanced paper and packaging machinery and equipment, enhancing overall recycling capabilities and throughput.

Precision engineering is essential to the success and sustainability of the paper industry by enabling the production of high-quality paper products, improving operational efficiency and driving innovation.

Clifton Rubber offers a range of Bespoke Rubber Components for various industry sectors, including paper and packaging. Our custom made products for your industry include:

We also provide Custom Polyurethane solutions tailored to specific industry needs.