Custom Automotive Rubber Components Manufacturer & Supplier

Clifton Rubber supplies the UK and European automotive industry with rubber and polyurethane components. We are experts in manufacturing custom moulding solutions from rubber or polyurethane, using our in house manufacturing capabilities to meet customer’s exact requirements.

Rubber components play a crucial role in the automotive industry, contributing to various aspects of vehicle design, manufacturing, and performance. The use of rubber in automobiles is diverse, ranging from tyres to seals, O-rings to seals, moulding and trim and vibration isolation components.

From moulding processes to precision engineering, discover how these components play an essential role in enhancing the automotive industry.

To find out more about each of our Capabilities in the Automotive Industry…

Read MoreCustom Automotive Rubber Components Industrial Services

Rubber Moulding For The Automotive Industry

We produce custom rubber moulded components for the automotive industry working with large companies and producing smaller volumes for classic and vintage car enthusiasts.

The automotive industry relies heavily on rubber and polyurethane components to enhance vehicle performance, comfort, design and safety. The versatility of rubber allows it to be used in a wide range of applications, due to rubber’s flexibility, resilience, and ability to withstand harsh environmental conditions. Rubber moulded components used in the automotive industry include:

- Grommets: Rubber grommets are used to protect and secure wiring, cables, and hoses as they pass through various parts of the vehicle.

- Insulators and Bushings: Rubber is used in suspension systems to provide a flexible interface between different components, absorbing vibrations for a smoother ride.

- Engine Mounts: Rubber engine mounts are crucial for isolating vibrations generated by the engine from the vehicle’s chassis.

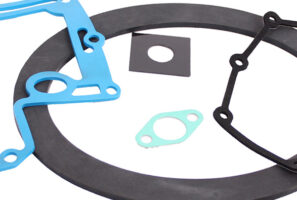

- O-Rings and Seals: O-rings and various seals made of rubber are used in the automotive industry to create watertight and airtight seals in components like fuel injectors, brake systems, and engine gaskets.

- Bellows: Bellows are used to protect critical components, such as steering joints and suspension components, from dust, dirt, and debris. They help extend the life of these components by preventing contamination.

- Bump Stops: Rubber bump stops are used in suspension systems preventing damage due to excessive motion.

- Weather Stripping: Rubber weather stripping is applied around doors, windows, preventing water, air, and noise from getting in.

- Pedal Pads: Rubber pedal pads provide a non-slip surface for brake, clutch, and accelerator pedals.

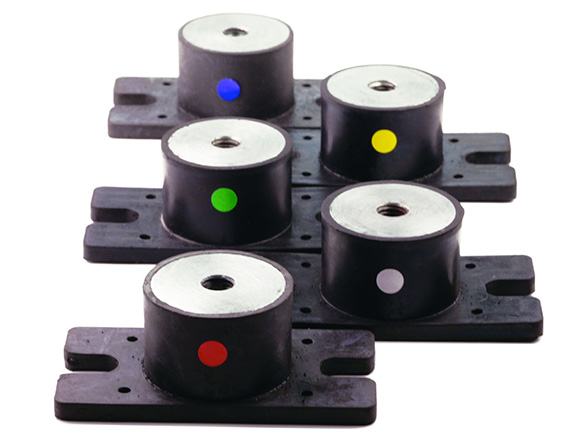

- Anti-Vibration Mounts: Used in various areas, including the exhaust system and engine, to reduce vibrations and noise.

- Trim Components: Such as dashboard covers, cup holders, and door handles and door mirror casing.

Polyurethane Moulding For The Automotive Industry

Polyurethane components find a range of applications in the automotive industry due to their versatility, durability, and specific material properties.

Polyurethane bumpers, seals, and interior components enhance safety and comfort. Its superior resilience and resistance to wear and tear result in longer-lasting parts, reducing maintenance and replacement costs.

Additionally, polyurethane’s ability to dampen vibrations and noise contributes to a smoother, quieter ride. The material’s low weight-to-strength ratio boosts fuel efficiency and reduces carbon emissions.

Here are several polyurethane components commonly used in the automotive sector:

- Bushings: Used in suspension systems to provide a more durable and longer-lasting alternative to traditional rubber bushings.

- Engine Mounts and Suspension Components: Polyurethane is used in the manufacturing of various suspension components, to offer improved durability, better resistance to chemicals and oils, and enhanced performance compared to traditional rubber.

- Bump Stops: Polyurethane bump stops are utilised in suspension systems to provide cushioning and prevent metal-to-metal contact.

- Steering Rack Bushings: Polyurethane bushings are used in steering rack mounts to improve steering responsiveness and reduce play in the steering system.

- Wheel Dampers and Mounts: Polyurethane wheel dampers are used to reduce vibrations and noise in the vehicle cabin by dampening vibrations transmitted through the wheels. Likewise, a vehicle’s body is protected by body mounts helping reduce vibrations.

- Interior Components: Various interior components, including armrests, console lids, and other trim pieces, are often moulded from polyurethane.

- Body Kits and Spoilers: Polyurethane is used in the manufacturing of body kits and spoilers used by many for aesthetic enhancements.

- Seals and Gaskets: Polyurethane seals and gaskets provide resistance to chemicals, weathering, and temperature variations.

- Trim Components: Such as dashboard covers, cup holders, and door handles and door mirror casing.

Polyurethane’s versatility and strength make it an ideal material for the automotive industry.

Rubber Covering including

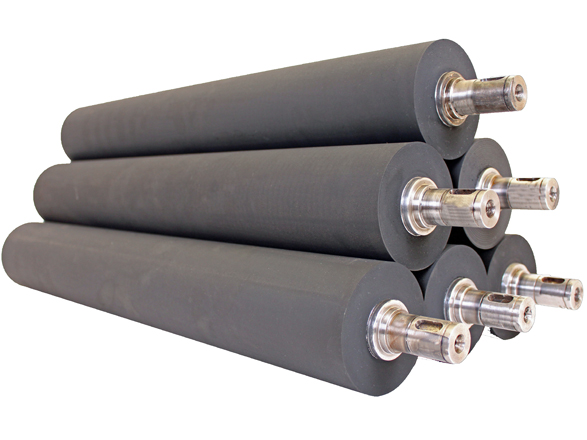

- Rubber Rollers For The Automotive Industry

- Rubber Wheels & Tyres The Automotive Industry

Rubber covering is used in the automotive industry in various ways. It’s main advantage is its ability to provide enhanced grip and traction, making it ideal for wheels and tyres. Rubber Covering protects against abrasion, impact, and corrosion, prolonging the lifespan of automotive parts.

Rubber covering, including rubber rollers, wheels, and tyres, brings significant advantages to the automotive industry.

Rubber rollers provide traction, damping, and support. Here are several ways in which rubber rollers are utilised in the automotive sector:

Conveyor Systems: Rubber rollers are used in conveyor systems during different stages of the vehicle manufacturing process, such as the movement of components along assembly lines.

Textile and Fabric Processing: Rubber rollers are used in the processing of interior textiles and fabrics. Machinery that applies adhesive, heat, or pressure to affix fabric to different components like seats or door panels.

Material Handling in Warehouses: Rubber rollers are used in material handling equipment within automotive distribution centres. The specific design and composition of rubber rollers depend on the requirements of the application.

Rubber wheels and tyres are essential components of modern cars and vintage vehicles. Solid wheels and tires do not contain air and are made of solid rubber or polyurethane. Often used in vehicles such as scooters, military, waste management and vintage cars.

Rubber covering solutions by Clifton Rubber offer excellent resistance to wear, tear, and chemicals, resulting in longer service life and reduced maintenance costs. Overall, rubber covering enhances productivity, efficiency, and safety.

Rubber Extrusion For The Automotive Industry

Rubber extrusions are used extensively in the automotive industry, for functions such as sealing, weatherproofing, and vibration isolation. Here are some common rubber extrusions used in the car industry:

Door Seals and Weather Stripping: Rubber extrusions are used as weather stripping in vehicles.

Vibration Dampeners: Used to dampen vibrations and reduce noise.

Windscreen Seals: Rubber extrusions are used in windscreens, providing a secure and weather-resistant seal.

Seals, O Rings and Gaskets: Rubber extrusions are used to create seals and gaskets in various automotive applications.

Protective Bumpers: Rubber extrusions are used as protective bumpers to absorb impact and prevent damage.

Vibration Isolation Mounts: Rubber extrusions are used to reduce vibrations and noise from the engine and other components.

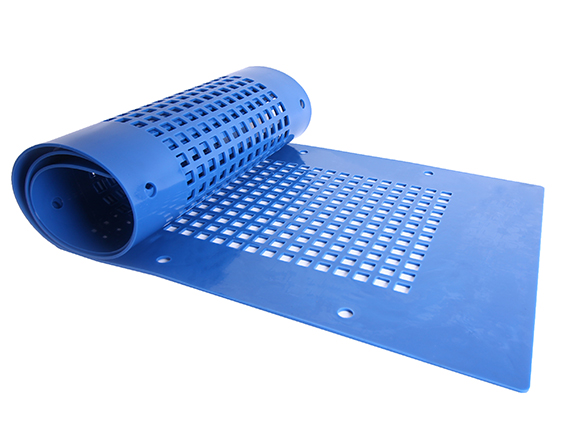

Rubber Sheet Conversion For The Automotive Industry

Rubber sheet conversion allows rubber sheets to be custom-cut and moulded into various shapes, allowing for precise fabrication of vehicle components. From flooring mats to soundproofing materials, rubber sheets offer excellent anti-slip properties, enhancing safety within cars. The resilience and weather resistance of rubber makes them ideal for creating durable seals and gaskets, reducing the risk of leaks and ensuring optimal vehicle functioning. In summary, rubber sheet conversion contributes to improved safety and durability for the automotive sector.

Here are some ways rubber sheeting is used in the automotive industry:

- Vehicle Flooring: Rubber sheeting is often used as flooring material in vehicles as it is slip resistant, cushioned and prevents noise and vibration.

- Gaskets and Seals: Used to create gaskets and seals in engines, transmissions, and other vehicle components to prevent fluid leaks.

- Vibration Isolation: Can be used as isolators or dampers to reduce vibration and noise in various vehicle components.

Precision Engineering For The Automotive Industry

Precision engineering plays a key role in the automotive industry. With its high-level accuracy and attention to detail, precision engineering ensures the production of intricately designed rubber and polyurethane components, optimising vehicle performance and safety.

Precision engineering is of paramount importance in the automotive industry due to its impact on various aspects of vehicle design, manufacturing, and performance.

Our precision engineering division maintains a comprehensive engineering capability providing in-house and sub-contract toolmaking, machining and fabrication services.

Clifton Rubber offers a range of Bespoke Rubber Components for various industry sectors, including automotive. Our custom made products for your industry include:

We also provide Custom Polyurethane solutions tailored to specific industry needs.