Custom Aerospace Rubber Parts Manufacturer & Supplier

We provide rubber and polyurethane solutions to meet our customer’s specific product requirements. The components we manufacture are used by our customers in various applications across the aerospace industry. They help to ensure the structural integrity of the aircraft and also provide comfort and safety for passengers and crew.

We have manufactured various bespoke rubber components for use by our customers in this sector, examples of which include hatch seals and gaskets, sheets and matting, and various moulded components to meet specific customer requirements.

From moulding processes to precision engineering, discover how these components play an essential role in enhancing the aerospace industry.

To find out more about each of our Capabilities in the Aerospace Industry…

Read MoreIndustrial Aerospace Rubber Products Manufacturing Services

Rubber Moulding For The Aerospace Industry

Rubber Moulding enables the production of custom rubber components that enhance vehicle performance and safety. From gaskets and seals to suspension bushings and engine mounts, rubber moulding ensures precise and durable parts. These components help reduce vibration and noise, leading to smoother rides and prolonged vehicle lifespan.

Rubber moulded components used in the aerospace industry include:

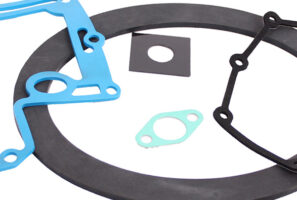

- Gaskets and Seals: sealing joints and connections in fuel systems, hydraulic systems, and other critical areas

- Rubber Bellows: ducting and bellows, are used in air distribution systems

- Joints and Couplings: to allow movement between different parts of the aircraft

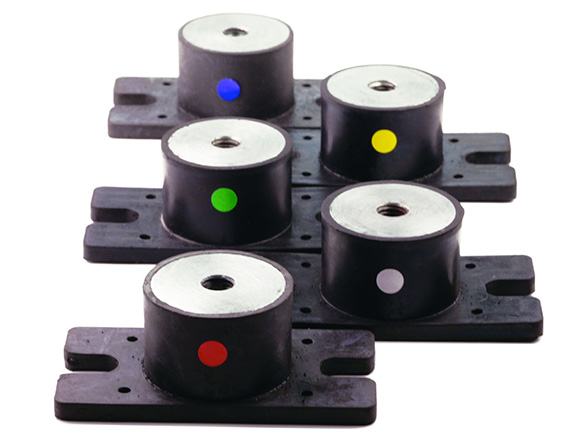

- Anti-Vibration Pads: used as anti-vibration solutions in avionics and sensitive equipment to protect against the effects of vibrations and shocks during flight.

- Vibration Isolation: rubber mounts and isolators are used to dampen vibrations and absorb shocks in aircraft engines and other mechanical systems.

Rubber’s versatility and ability to withstand harsh conditions make it ideal for aeronautical applications.

Polyurethane Moulding For The Aerospace Industry

Polyurethane moulding offers significant benefits to the aerospace industry. With its exceptional versatility, it allows the creation of complex, lightweight, and durable parts.

Polyurethane bumpers, seals, coatings and interior components enhance safety and comfort. Its superior resilience and resistance to wear and tear result in longer-lasting parts, reducing maintenance and replacement costs.

Additionally, polyurethane’s ability to dampen vibrations and noise contributes to a smoother, quieter ride. The material’s low weight-to-strength ratio boosts fuel efficiency and reduces carbon emissions, which is key in the aerospace industry..

Here are some common polyurethane moulded components used in the aerospace industry:

- Aircraft Bumpers

- protective components designed to absorb and mitigate the impact forces that may occur during various ground handling operations, such as docking, pushback, or towing.

- Seals and Gaskets:

- providing effective sealing solutions for various aircraft components. It is resistant to wear, chemicals, and environmental factors.

- Coatings:

- Polyurethane coatings are applied to aircraft surfaces to enhance durability, protect against corrosion, and provide resistance to weathering and harsh environmental conditions.

- Aircraft Interiors:

- used in various interior components, including armrests, tray tables, etc. Its versatility allows for the creation of aesthetically pleasing and functional interior elements.

Polyurethane’s versatility and strength make it an ideal material for the aerospace industry.

Rubber Covering including

- Rubber Rollers For The Aerospace Industry

- Rubber Wheels & Tyres The Aerospace Industry

Rubber covering benefits the aerospace industry in various applications. One key advantage is its ability to provide enhanced grip and traction, making it ideal for tyres, wheels and baggage conveyor belts. Rubber covering protects critical surfaces from abrasion, impact, and corrosion, prolonging the lifespan of components.

Rubber covering, including rubber rollers, wheels, and tyres, brings significant advantages to the aerospace industry.

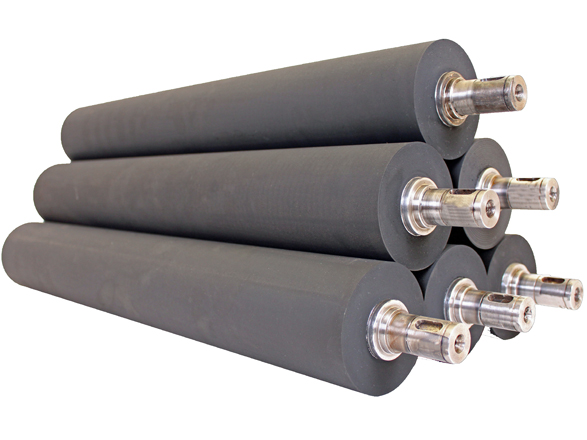

Rubber rollers are used for various applications that require precision, reliability, and resistance to harsh environmental conditions.

Rollers are used in various applications in the aerospace industry including:

- Conveyor Rollers: used to guide, tension, and control the movement of flexible materials during manufacturing processes.

- Transport Rollers for Ground Support Equipment: Rubber rollers are used in ground support equipment, such as aircraft tugs to facilitate the movement of aircraft on the ground. These rollers are often part of caster wheels or conveyor systems in ground handling equipment. They are also used in ground handling equipment such as baggage handling belts.

The selection of rubber rollers in the aerospace industry is based on factors such as material compatibility, resistance to chemicals and temperature variations, precision requirements, and durability. These rollers contribute to the efficiency and quality of aerospace manufacturing processes.

Rubber wheels and tyres are used in the aerospace industry in areas such as:

- Ground support vehicles

- Trailers & Tugs

- Airport Transport Systems

- Aircraft stands

Rubber covering solutions offer excellent resistance to wear, tear, and chemicals, resulting in longer service life and reduced aircraft maintenance costs.

Rubber Extrusion For The Aerospace Industry

Rubber extrusions cater to a wide range of applications in the aerospace industry.

Common uses of rubber extrusions include:

Seals and Gaskets: to create seals and gaskets that provide airtight, watertight, and dustproof seals of doors, windows, access panels, and various joints on an aircraft. These seals help prevent air and water infiltration, contribute to noise reduction, and ensure the cabin remains pressurised during flight.

Vibration Isolation: to absorb vibrations generated by aircraft engines and other equipment.

Trim and Protective Seals: in cargo doors, landing gear components, and other areas where protection against physical impact is necessary.

Cable and Wiring Management: for cable and wiring management, providing a protective covering for electrical components.

Expansion Joints: rubber extrusions are used as expansion joints to accommodate movement caused by temperature variations and structural flexing, maintaining a secure seal in critical areas.

The versatility of rubber extrusions allows for the creation of tailored solutions that meet the stringent performance, durability, and safety standards required in the aerospace industry.

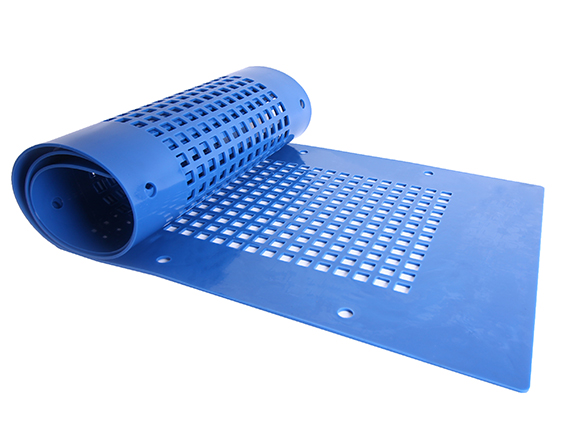

Rubber Sheet Conversion For The Aerospace Industry

Rubber sheet conversion allows rubber sheets to be custom-cut and moulded into various shapes, allowing for precise fabrication of aerospace components. From flooring mats to soundproofing materials, insulation, rubber sheets offer excellent anti-slip properties, enhancing safety within aircraft.

They also act as protective layers for baggage and cargo, shielding it from damage during flight. The use of rubber sheets in aerospace is diverse, contributing to the overall performance, safety, and comfort of aircraft.

Precision Engineering For The Aerospace Industry

Precision engineering plays a crucial role in the aerospace industry. With its high-level accuracy and attention to detail, precision engineering ensures the production of intricately designed rubber and polyurethane components, optimising the performance and safety of aircraft.

Our precision engineering division maintains a comprehensive engineering capability providing in-house and sub-contract toolmaking, machining and fabrication services.

Clifton Rubber offers a range of Bespoke Rubber Components for various industry sectors, including aerospace. Our custom made products for your industry include:

We also provide Custom Polyurethane solutions tailored to specific industry needs.