Custom Military Grade Rubber Component Suppliers & Manufacturer

Find out more about Clifton Rubber’s advanced rubber and polyurethane components designed for the defence industry. From rubber moulding to precision engineering, discover durable, efficient, and innovative materials that work across a range of applications used by the defence industry. Clifton Rubber is your trusted supplier with over 50 years of manufacturing experience.

Rubber and polyurethane components are ideal for use in the defence industry due to their durability, versatility and resilience. They are ideal for the wide range of challenging environments and applications typically encountered in the defence sector.

Clifton Rubber is a leading supplier to this sector. We have manufactured various bespoke rubber components for defence customers and are happy to discuss any project unique to this sector.

From moulding processes and extrusion to precision engineering, discover how these components play an essential role in enhancing the defence industry.

To find out more about each of our Capabilities in the Defense Industry…

Read MoreIndustrial Military Grade Rubber Component Manufacturing Services

Rubber Moulding For The Defence Industry

Rubber moulded components are ideal to meet the specific needs and challenges faced by military equipment and systems.

Here are some common uses of rubber moulded components in defence:

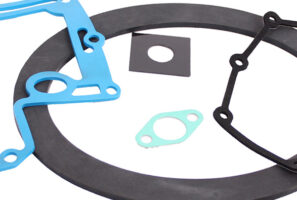

- Seals and Gaskets: to create watertight, airtight, and dust-resistant seals in a wide range of defence equipment.

- O-Rings and Seals: for preventing leaks in aircraft components, vehicles, and weapons. Also used in hatches and entrances on military vehicles, ships, and aircraft.

- Door Hatch Resilient Mounts: to protect hatches.

- Boat Fenders: to protect boats and other floating vehicles.

- Protectors: for barrels, aerials and a whole range of other equipment.

- Anti-Vibration Mounts: to isolate sensitive equipment, from vibrations in military vehicles, ships and aircraft.

Rubber moulded components contribute to efficiency, safety, security and durability in the defence industry.

Polyurethane Moulding For The Defence Industry

Polyurethane moulding offers exceptional versatility, with resistance to abrasion, impact, and weathering, making them suitable for various defence applications such as:

- Seals and Gaskets: used in various military equipment, to provide resistance to external conditions.

- Vibration Isolators and Dampeners: used to protect sensitive equipment.

- Underwater and Marine Components: Polyurethane is used in components such as seals, propellers, and buoyancy materials for underwater and marine applications, including submarines and underwater vehicles.

- Protective Equipment: Some advanced body armour and protective gear use polyurethane componentsl.

Polyurethane components are used extensively in the defense industry for their ability to withstand extreme conditions, including temperature variation. Polyurethane is low maintenance, requiring minimal upkeep and providing long-lasting performance.

Rubber Covering including

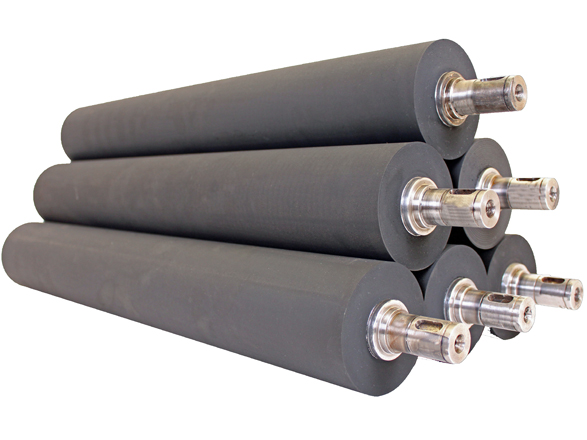

- Rubber Rollers For The Defence Industry

- Rubber Wheels & Tyres For The Defence Industry

Rubber covering, including rubber rollers, wheels, and tyres, brings significant advantages to the construction industry.

Rubber covering, including rubber rollers, wheels, and tyres, are used widely across the defence sector.

Rubber rollers provide exceptional traction and grip, facilitating the movement of defence equipment with enhanced stability and control.

Rollers are used in various applications in the construction industry including:

- Packing and Distribution: Polyurethane rollers are used to help with packing materials such as military supplies

- Material Handling Equipment: Such as conveyor systems for the movement of equipment, supplies, and materials.

- Cranes and Lifts: To support heavy loads and ensure smooth movement along tracks and rails.

- Anti-Slip and Traction: to provide anti-slip and traction properties in military vehicles and equipment.

They also offer excellent shock absorption, reducing vibration and minimising damage to defence equipment.

Rubber wheels and tyres are an integral part of the logistical capabilities of military forces ensuring equipment can be rapidly deployed for military operations.

They are typically used in:

- Military Vehicles: such as tanks and aircraft and portable transport vehicles for weapons and other supplies

- Material Handling Equipment: such as cranes and forklifts for military supplies.

Rubber covering solutions offer excellent resistance to wear, tear, and chemicals, resulting in longer service life and reduced maintenance costs for the defence sector.

Rubber Extrusion For The Defence Industry

Rubber extrusion are used for a variety of defence applications as they allow excellent protection and versatility in high pressure environments.

Common uses of rubber extrusions in Defence are:

- Seals and Gaskets: Rubber extrusions are used to create seals and gaskets in various military equipment and for doors and hatches.

- Protective Bumpers: Rubber extrusions are used as protective bumpers on equipment and machinery to absorb impact and prevent damage.

- Soundproofing Seals: Used in soundproofing applications to insulate military vehicles.

- Chemical Resistance: rubber extrusions with chemical-resistant properties are used in the production of seals and gaskets.

Rubber extrusion also allows for the creation of complex shapes and designs, catering to specific military requirements. With Clifton Rubber, our extrusion capabilities enhance defence efficiency, and work well in harsh, unpredictable environments.

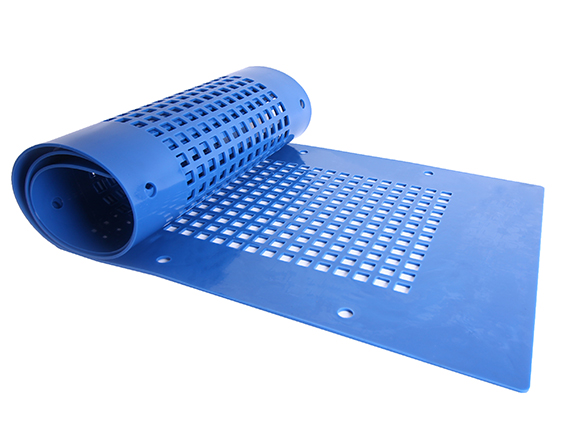

Rubber Sheet Conversion For For The Defence Industry

At Clifton Rubber, we specialise in transforming rubber sheeting into tailor-made rubber gaskets, seals, and other non-metallic components such as washers, insulations, and sheeting.

Our rubber gaskets are crafted according to the customer’s specifications, offering a wide range of shapes and sizes to accommodate even the most unique requirements.

Rubber Sheeting is used in defence for applications such as:

- Underwater Applications

- Vibration Isolation

- Flooring, Coverings, and Mats

- Soundproofing

- Gaskets and Seals

- Electrical Insulation and Damp Proofing

- Protective Pads and Bumpers

- Chemical, Biological, Radiological, and Nuclear (CBRN) Protection

Rubber sheets offer a wide range of applications in defence, contributing to the waterproofing, insulation, protection, and comfort of military equipment. Their ease of use and adaptability make them invaluable.

It is often a crucial component of military equipment which undergoes demanding operational uses. While many of our rubber gasket products are cut from rubber sheet materials, we also have the capability to manufacture fully moulded gaskets and seals. Additionally, we provide the option of supplying parts with a self-adhesive backing, available in custom lengths, widths, and thicknesses.

Precision Engineering For The Defence Industry

By employing advanced manufacturing techniques, rubber products can be precisely engineered to meet the specific requirements of defence projects.

This level of precision is essential for military technology and equipment. Accuracy and reliability is key for sea, land and air systems and equipment. Successful operations and the protection of personnel is aided by the reliability of precision made components.

Clifton Rubber offers a range of Bespoke Rubber Components for various industry sectors, including defence. Our custom made products for your industry include:

We also provide Custom Polyurethane solutions tailored to specific industry needs.