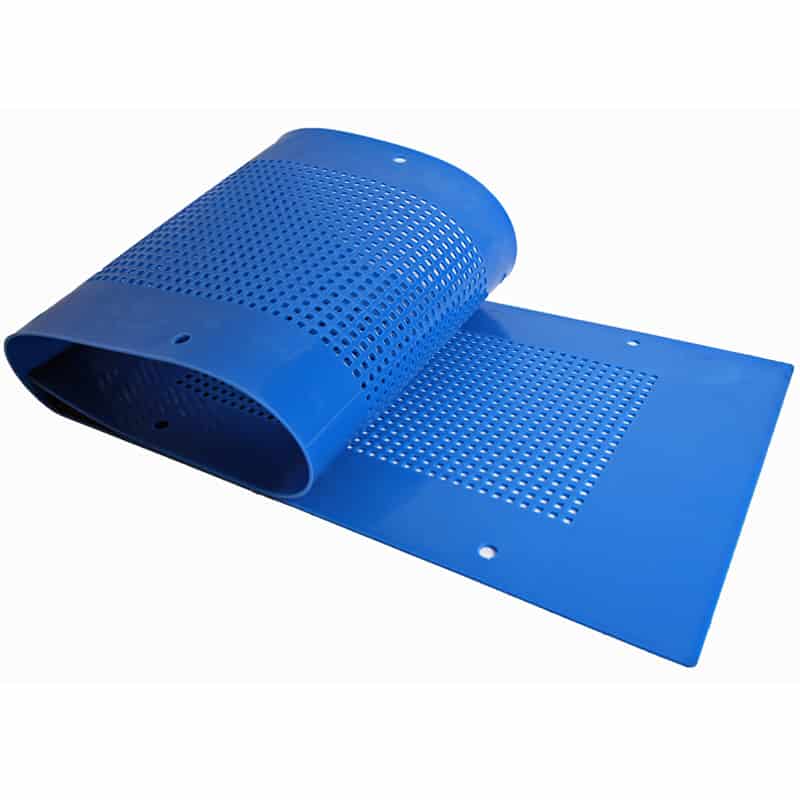

Custom Screening Mats

Bespoke Screening Mats

We produce screening mats to meet customer’s bespoke requirements in a range of shapes, colours and sizes. Screening mats are used in waste recycling facilities to sort and separate materials based on their size. A mat usually consists of a large, perforated surface or mesh through which smaller particles can pass while larger items are retained on top for further sorting. This process helps to streamline further sorting processes by categorizing materials into size-specific groups, which can then be directed to appropriate recycling streams in the waste management process.

We have produced various types of screening mats for Recycling customers including:

- Vibrating Screens: These mats are often integrated into vibrating screens, which shake the materials to encourage efficient separation.

- Rotary Screens: Drum-like screens rotate to facilitate the passage of smaller particles while larger ones move along the drum’s length.

Applications these have been used for include:

- Paper and Cardboard Separation: Separates small paper pieces from larger cardboard.

- Plastic Sorting: Helps in distinguishing small plastic fragments from larger items.

- Glass Recycling: Screens out fine glass particles from larger shards.

Benefits of screening recycled materials using a screening mat:

- Improved Efficiency: Speeds up the sorting process, making recycling operations more efficient.

- Enhanced Material Quality: By accurately sorting materials, it ensures that contaminants are minimized, improving the quality of recycled outputs.

- Cost-Effective: Reduces manual labour by automating part of the sorting process.