Quality Wins a New Rubber Moulding Customer

We were recently approached by a long-established UK manufacturing company to produce a rubber collet which was bespoke to their needs.

The company is a market leader in the manufacture of variable rate spraying equipment, and their products are used across a range of global industries and applications.

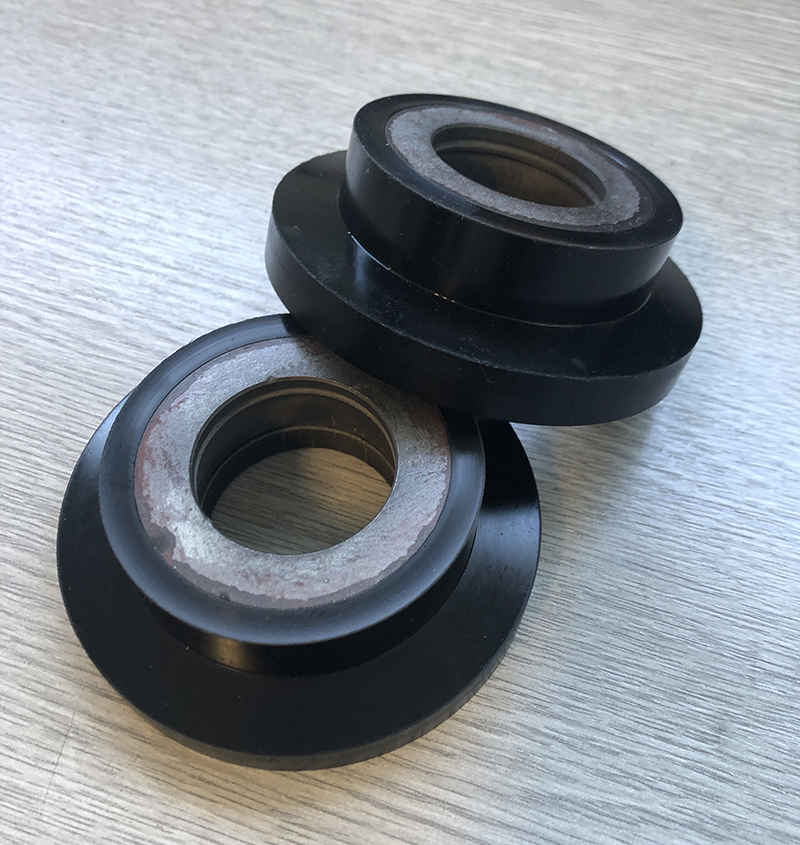

The rubber collet they required acts as a valve to control the flow of liquid in variable rate sprayer nozzles. To achieve accurate flow rates the customer required a high-quality rubber nozzle which was durable, uniform in shape and of the correct material hardness. Unfortunately, the parts they had been receiving from a foreign supplier had not met these requirements and they were getting more than a 60% failure rate, which was simply not acceptable.

The customer approached the Clifton Rubber team at a trade exhibition and asked for help. He needed a reliable supplier.

The customer issued us with a drawing of the part against which our estimators could confirm costs. Prices were quickly agreed, orders received, and our design engineers set about designing the mould tool, which was then manufactured in-house by our dedicated toolroom engineers. We quickly had a first off sample produced for our customer to inspect, test, and approve, before we went into full batch production.

The new rubber collets proved to be a success. They are fully tested by the customer before use and since switching to Clifton Rubber there has been significant improvement in quality with a minimal failure rate. This has helped the customer achieve consistently accurate flow rates whilst saving costs.

The customer’s Sales Manager commented:

“Quality is key. It must be top notch. It looks simple but it’s a very technical part and precision is of the utmost importance. We needed to source a new supplier who were reliable, and UK based.

Clifton Rubber made us some samples and we simply couldn’t believe how good they were. The quality was second to none.”