Polyurethane Screen Mats for the Mining & Quarrying Industry

In the demanding environments of mining and quarrying, material screening plays a critical role in separating valuable minerals and aggregates. The efficiency and longevity of your screening equipment depend heavily on the quality of your screen mats. At Clifton Rubber, we manufacture Polyurethane Screen Mats that offer exceptional wear resistance, high throughput, and extended service life, making them an essential component for operators looking to maximise productivity and minimise downtime.

Custom Polyurethane Screen Mat Manufacturer & Supplier for the Mining & Quarrying Industry

What Are Polyurethane Screen Mats?

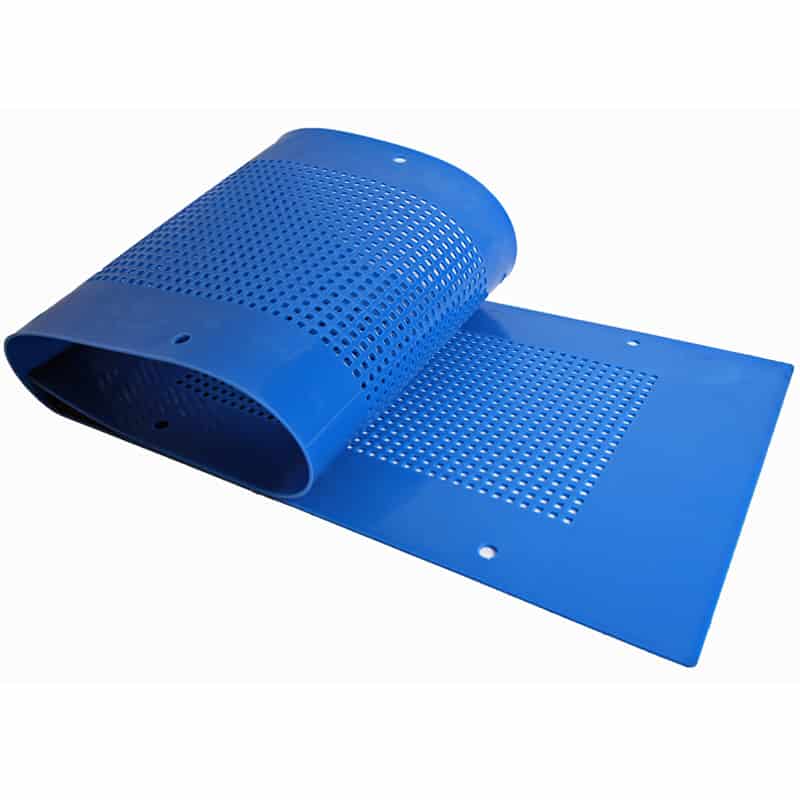

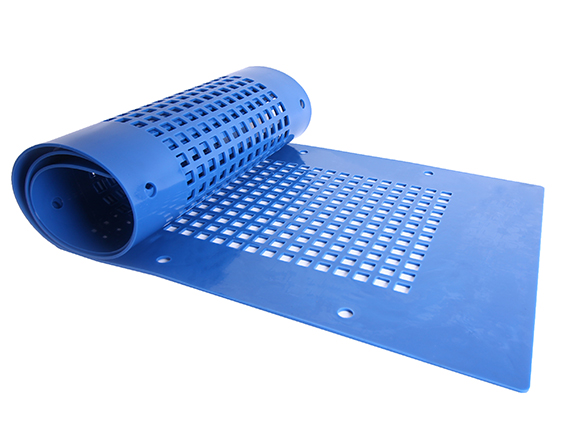

Polyurethane screen mats are flexible, abrasion-resistant panels used in screening machines to separate bulk materials by size. Manufactured from tough polyurethane compounds, these mats are ideal for heavy-duty applications in mining and quarrying, where abrasive and high-impact materials can quickly degrade traditional screen media.

They are typically used to replace woven wire screens or rubber screens, offering greater durability and improved performance across wet and dry screening processes.

Use of Polyurethane Screen Mats in Mining & Quarrying

Aggregate and Mineral Screening

Polyurethane mats are used in primary, secondary, and tertiary screening stages for crushed stone, gravel, sand, coal, iron ore, and other raw materials.

Wet Screening and Dewatering

Due to their non-corrosive properties, polyurethane screen mats perform exceptionally in wet screening and dewatering operations, ensuring clean separation and reduced blinding.

Vibrating Screens and Sizing Equipment

Fitted to vibrating screen decks, polyurethane mats handle high vibration and load, maintaining consistent aperture shape and efficient material flow.

Recycling and Rescreening Systems

In both quarry and mine recycling setups, screen mats are critical for separating reusable aggregates or fines from oversized material.

What Solutions Do We Provide?

Custom Screen Mat Designs

Clifton Rubber supplies a wide range of modular and tensioned polyurethane screen mats, including square, slotted, and round apertures tailored to your specific application and screen deck.

High-Performance Polyurethane Compounds

Our mats are moulded from premium-grade polyurethane, delivering excellent resistance to abrasion, tearing, and chemical exposure—ideal for prolonged exposure to tough materials.

Modular and Replaceable Panels

We offer modular systems that allow for quick and easy replacement of worn sections, reducing downtime and improving on-site efficiency.

Anti-Blinding and Self-Cleaning Features

Many of our screen mats are designed with flexible sections or tapered apertures that reduce pegging and blinding, keeping screening capacity high.

Noise and Vibration Reduction

Compared to steel mesh screens, polyurethane mats reduce operational noise and dampen vibration, enhancing both safety and operator comfort.

Why Choose Clifton Rubber?

Decades of Manufacturing Experience

With over 50 years of experience producing precision-moulded rubber and polyurethane components, Clifton Rubber is a trusted name in industrial screening solutions.

Full In-House Design & Tooling Capabilities

We provide a complete service from design to production, working closely with customers to ensure each screen mat meets their exact equipment and performance requirements.

Compatibility with Major Screen Brands

Our screen mats are suitable for use with a wide range of screening machinery, including leading OEMs in the mining and quarrying sectors.

Built to Last in Harsh Environments

Our polyurethane screen mats are proven in some of the most extreme quarrying and mining conditions, delivering dependable performance shift after shift.

About Clifton Rubber

Clifton Rubber is a UK-based manufacturer of high-quality rubber and polyurethane products serving a wide range of sectors, including mining, quarrying, construction, transport, and renewables. Our commitment to quality, innovation, and customer service has earned us a reputation for reliability and excellence.

In the mining and quarrying industry, we specialise in wear-resistant screening products such as polyurethane screen mats, dewatering panels, and modular screening systems. Our engineering team works directly with operators and equipment manufacturers to develop screening solutions that deliver lasting performance and cost efficiency.

Need tough, reliable screen mats for your quarry or mine?

Talk to Clifton Rubber today about our range of Polyurethane Screen Mats and discover how we can help optimise your screening operations.