A Polyurethane Solution Provides a Quieter Working Environment

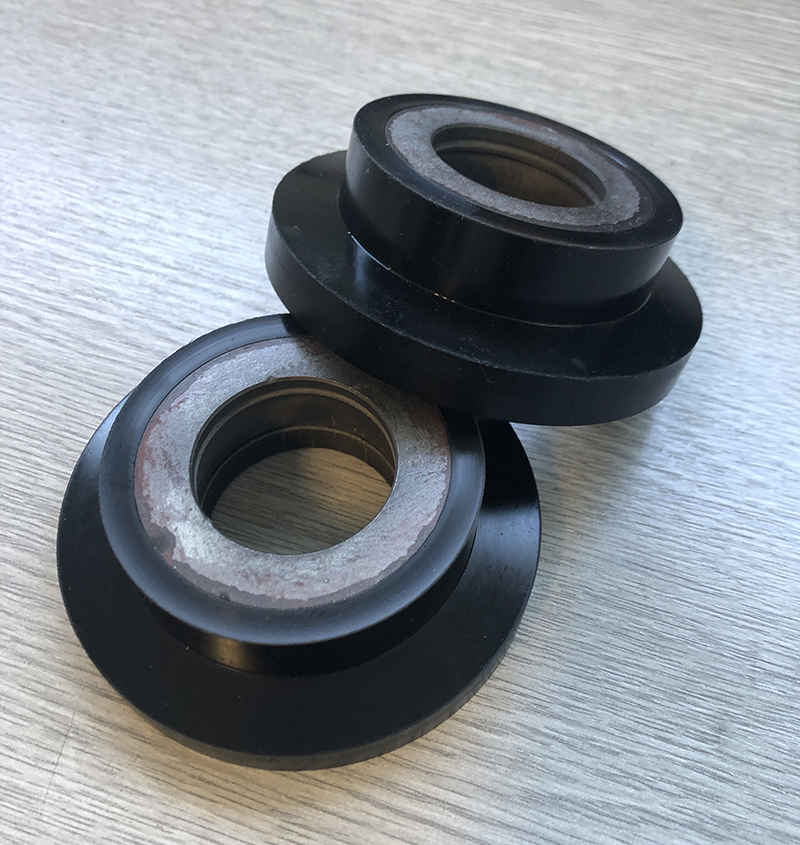

We have just completed a successful polyurethane moulding project for a Maintenance company specialising in Lifting Equipment.

The company use carriage wheels on a metal track for lifting equipment in their workshop. However, the sound of metal on metal is quite loud and distracting for those working with the equipment below. They wanted a more silent solution.

The company approached our in-house design team who looked at whether we could come up with a solution whereby the wheels were covered in rubber, to see if this would make things less noisy.

Design Team Input

Our design team looked at a few options, both rubber and polyurethane. The decision was made that a polyurethane covering would be a more cost-effective solution.

Our polyurethane production team set to work to create a new mould for the coating. We then created eight samples – enough for one of their lifting trolleys, so the customer could run a trial.

This resulted in a very happy customer. There was a noticeable reduction in noise and the poly covered carriage wheels will be put in place across the whole workshop.

We now have a second batch of 28 units in production with more to follow.

Phi Holt, our Sales Executive commented:

“We were able to work with the customer to provide a solution that was cost effective and created a safer working environment for their workforce. Our in-house design and production teams were able to produce some prototypes for trial and then we worked together to create the final product for introduction into their workshop.”