Flip Flow Screen Mats for the Recycling Industry

In the recycling industry, where materials are often wet, sticky, or irregular in size, traditional screening systems can struggle. Clifton Rubber’s flip flow screen mats offer a powerful solution—flexible, hard-wearing rubber mats that vibrate dynamically to separate even the most challenging materials. Engineered for efficiency and durability, they’re a vital component for modern recycling and material recovery operations.

Custom Flip Flow Screen Mat Manufacturer & Supplier for the Waste & Recycling Industry

What Are Flip Flow Screen Mats?

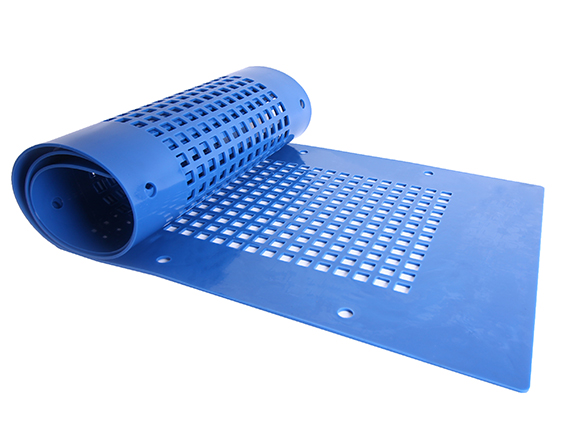

Flip flow screen mats are highly elastic rubber panels used in dynamic screening systems. Unlike static screens, flip flow mats oscillate at high frequencies and amplitudes to keep materials moving. This reduces clogging and enhances the separation of wet, sticky, or fine materials that would otherwise block traditional screens.

Key Features of Clifton Rubber’s Flip Flow Screen Mats:

- Elastic, High-Tensile Rubber Material: Built to endure heavy, continuous motion and impact.

- Optimised Openings: Precisely designed apertures for effective material separation.

- Non-Clogging Design: The flexing action prevents blinding and material build-up.

- Compatible with All Major Screening Units: Custom-manufactured to fit a wide range of flip flow screening machines.

- Weather and Chemical Resistance: Performs reliably in wet, corrosive, or abrasive conditions.

Applications of Flip Flow Screen Mats in the Recycling Industry

1. Household & Municipal Waste Screening

Separates fine and wet materials from general waste streams, improving recovery rates and reducing contamination.

2. Plastic, Rubber & Textile Recycling

Ideal for screening light and flexible materials that tend to wrap around or clog standard screens.

3. Organic & Compost Waste Processing

Efficiently separates moist organic waste and contaminants during compost production.

4. Construction & Demolition Waste Recovery

Screens fine aggregates and debris, even when wet, supporting accurate sorting and recycling of materials.

5. Metal & Glass Recycling Plants

Helps process abrasive materials like crushed glass or shredded metals without screen failure or excessive wear.

Benefits of Clifton Rubber’s Flip Flow Screen Mats

1. Superior Screening of Wet or Sticky Materials

The dynamic motion and rubber elasticity of our mats ensure continuous screening, even with high-moisture or fibrous materials.

2. Minimal Downtime & Maintenance

Reduced blinding means fewer stoppages and lower maintenance costs for recycling operations.

3. Extended Lifespan in Harsh Environments

Highly resistant to wear, impact, chemicals, and weather—ideal for demanding applications.

4. Custom-Fit to Your Equipment

Clifton Rubber offers bespoke flip flow mats tailored to your specific machine type and screening requirements.

5. Improved Throughput & Efficiency

Higher screening accuracy and consistent material flow support better plant performance and output quality.

Why Choose Clifton Rubber for Flip Flow Screen Mats?

1. Specialists in Rubber Screening Products

With extensive experience in rubber engineering, Clifton Rubber produces screen mats built for demanding recycling environments.

2. Custom Manufacturing & Technical Expertise

We work closely with our clients to develop flip flow mats that precisely match their equipment and material handling needs.

3. Quality Materials & Production Processes

All our products are made using top-grade rubber compounds and strict quality control to ensure optimal performance.

4. Reliable Supply & Ongoing Support

We provide consistent product availability and after-sales support for recycling businesses across the UK and internationally.

5. Trusted by Industry Leaders

Our flip flow mats are trusted by major recycling plants and waste processors who demand performance and reliability.

For efficient screening of the most challenging recycling materials, Clifton Rubber’s flip flow screen mats are the smart choice. Get in touch with our team to discuss how we can support your screening operations.