Ceramic & Rubber Rollers for the Mining & Quarrying Industry

In the rugged world of mining and quarrying, reliable material handling equipment is essential for efficient operations. Rollers used in conveying, crushing, and screening systems are exposed to extreme wear, corrosion, and high-impact loads. At Clifton Rubber, we manufacture Ceramic & Rubber Rollers that combine the strength of ceramic with the resilience of rubber to deliver long-lasting performance in harsh environments.

Whether used in conveyor systems or processing equipment, our rollers are engineered to reduce downtime, improve grip, and extend equipment life, making them an ideal choice for demanding mining and quarrying applications.

Custom Ceramic & Rubber Roller Manufacturer & Supplier for the Mining & Quarrying Industry

What Are Ceramic & Rubber Rollers?

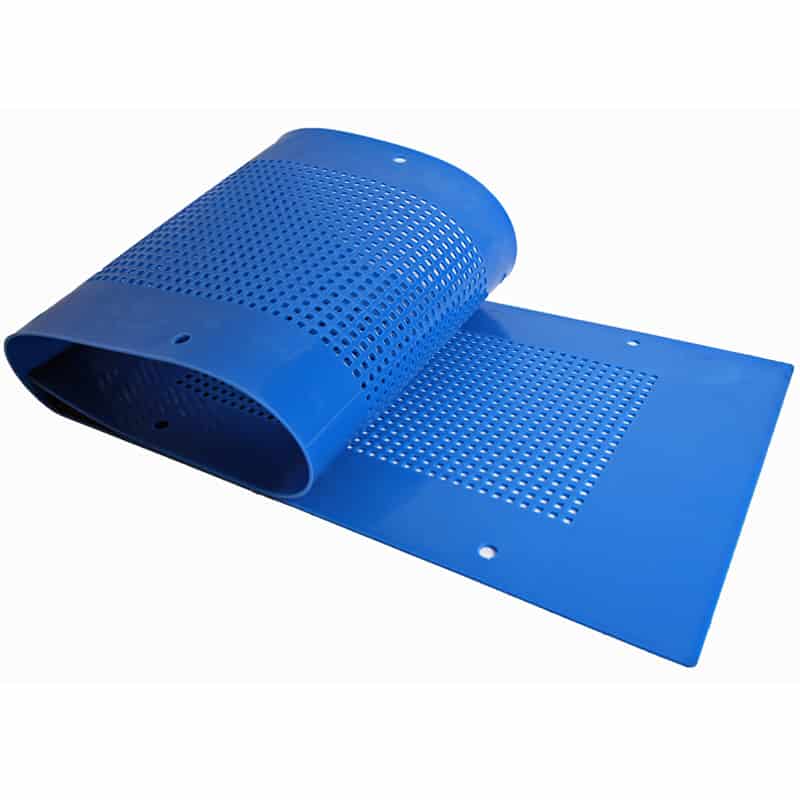

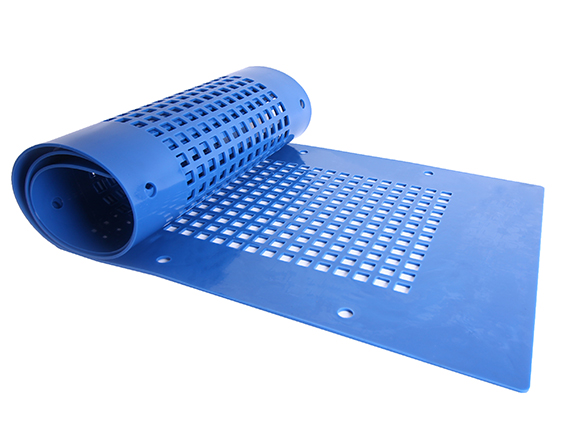

Ceramic & rubber rollers are precision-engineered components consisting of a rubber base with embedded ceramic segments or tiles. This hybrid design offers enhanced resistance to abrasion, impact, and slippage, particularly in high-load, high-speed environments commonly found in mining and quarrying operations.

These rollers are most often used in conveying and material transfer systems where traditional rollers would wear prematurely or lose traction under heavy-duty use.

Use of Ceramic & Rubber Rollers in Mining & Quarrying

Conveyor Systems

In primary and secondary crushing plants, rollers must transport heavy loads of raw materials across varying terrain. Ceramic & rubber rollers provide excellent grip and resistance to wear from sharp, abrasive materials like crushed stone, ore, and aggregates.

Material Processing Equipment

Rollers are critical in equipment such as screens, feeders, crushers, and washing plants. The ceramic elements help resist degradation from slurry, dust, and continuous high-impact operations.

Tensioning and Drive Applications

Used in drive and tensioning roles, ceramic & rubber rollers maintain consistent surface traction, preventing slippage and ensuring stable belt alignment even under wet or dusty conditions.

Transfer Points and Load Zones

In high-impact zones, such as material drop points, these rollers absorb shock and protect belts from damage, reducing the risk of downtime and costly repairs.

What Solutions Do We Provide?

High-Quality Material Blends

Clifton Rubber uses durable, high-grade rubber compounds combined with carefully placed ceramic inserts to achieve a balance of flexibility, traction, and abrasion resistance.

Custom Design and Engineering

We manufacture rollers in various diameters, lengths, and ceramic configurations to suit specific applications and equipment. Our team can work with OEMs and site engineers to develop bespoke solutions.

Extended Service Life

Ceramic & rubber rollers last significantly longer than standard rubber or steel rollers, reducing maintenance intervals and total cost of ownership.

Enhanced Belt Protection

The combination of rubber cushioning and ceramic traction minimises belt wear and slippage, helping maintain conveyor efficiency and reducing downtime.

Reduced Maintenance Requirements

Thanks to their high resistance to wear and corrosion, these rollers help minimise replacement frequency and associated operational disruption.

Why Choose Clifton Rubber?

Proven Industry Expertise

With over 50 years of experience manufacturing rubber and polyurethane components, Clifton Rubber has become a trusted name in industrial roller solutions.

UK-Based Manufacturing

All our products are designed and produced in-house in the UK, ensuring complete control over quality, lead times, and customisation.

End-to-End Service

From initial design to production and after-sales support, our team works closely with clients to deliver durable, high-performing rollers tailored to specific mining and quarrying challenges.

Trusted by Leading Operators

Our rollers are used by major companies in the mining and quarrying sectors, valued for their longevity, performance, and reliability in some of the world’s most demanding environments.

About Clifton Rubber

Clifton Rubber is a leading UK manufacturer of rubber and polyurethane components, supplying specialist solutions to industries including mining, quarrying, transport, construction, renewables, and more. Our focus on engineering excellence and material innovation allows us to create components that perform reliably in the most challenging environments.

For the mining and quarrying industry, we provide a wide range of wear-resistant products such as screen mats, bump stops, and ceramic & rubber rollers. Whether you’re looking to improve conveyor performance or reduce maintenance in processing equipment, our experienced team is here to support your operations with long-lasting, efficient solutions.

Looking to reduce wear and downtime in your conveying systems?

Get in touch with Clifton Rubber to learn more about our high-performance Ceramic & Rubber Rollers for mining and quarrying applications.