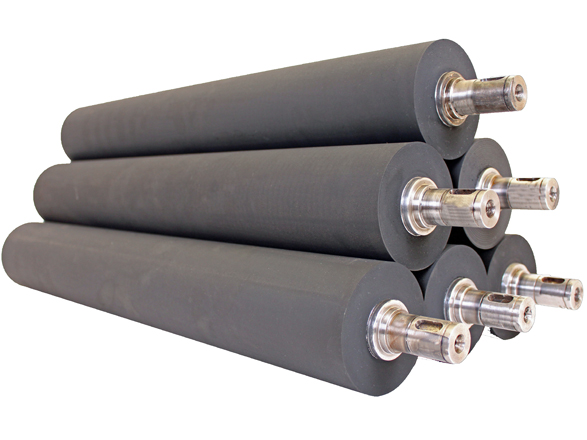

Bleaching Rollers for the Textiles & Clothing Industry

Bleaching rollers play a critical role in textile manufacturing by ensuring even application of bleaching agents to fabrics, improving whiteness and fabric quality. Clifton Rubber specialises in manufacturing premium bleaching rollers that provide durability, precision, and efficiency for textile processing.

Custom Bleaching Roller Manufacturer & Supplier for the Textiles & Clothing Industry

Our rollers are built to withstand harsh chemical environments and high-speed production processes, ensuring long-lasting performance and superior results.

What Are Bleaching Rollers?

Bleaching rollers are essential components in textile processing lines, helping to evenly distribute bleaching agents across fabrics. These rollers improve fabric whiteness, remove impurities, and prepare textiles for dyeing or finishing treatments.

Features of Clifton Rubber’s Bleaching Rollers:

- Chemical-Resistant Rubber Compounds: Engineered to withstand exposure to bleaching agents and harsh chemicals.

- Precision Manufacturing: Ensures consistent pressure and uniform treatment across the fabric surface.

- High Durability: Designed for extended use in continuous textile processing environments.

- Custom Sizes & Configurations: Tailored to fit specific textile machinery and processing requirements.

Applications of Bleaching Rollers in the Textiles & Clothing Industry

1. Fabric Pre-Treatment

Bleaching rollers are used in the initial stages of textile production to remove natural and synthetic impurities, enhancing fabric absorbency.

2. Even Bleaching Agent Distribution

They ensure uniform application of bleaching solutions, preventing streaks and discolouration in fabrics.

3. Preparation for Dyeing & Printing

By whitening and purifying textiles, bleaching rollers create an ideal base for subsequent dyeing, printing, and finishing processes.

4. High-Speed Textile Processing

Designed for use in modern textile machinery, these rollers maintain precision and efficiency even at high operational speeds.

Benefits of Clifton Rubber’s Bleaching Rollers

1. Superior Chemical Resistance

Our rollers are made from advanced rubber compounds that resist degradation from strong bleaching agents.

2. Extended Lifespan

Durable construction minimises wear and tear, reducing maintenance and replacement costs.

3. Consistent & Reliable Performance

Precision engineering ensures smooth and even fabric treatment, improving overall production quality.

4. Custom-Made Solutions

We offer tailor-made bleaching rollers to fit different machine specifications and production requirements.

5. Efficiency & Cost Savings

By optimising fabric processing, our rollers contribute to reduced waste, lower chemical consumption, and increased production efficiency.

Why Choose Clifton Rubber for Bleaching Rollers?

1. Decades of Industry Expertise

With years of experience in rubber manufacturing, we produce high-performance rollers trusted by textile manufacturers.

2. Advanced Manufacturing Techniques

Our rollers are engineered using state-of-the-art technology to deliver precision and durability.

3. Custom Engineering & Support

We collaborate with clients to develop rollers that meet their specific textile processing needs.

4. Strict Quality Control

Every roller undergoes rigorous testing to ensure it meets the highest industry standards.

5. Global Industry Trust

Leading textile manufacturers rely on Clifton Rubber for high-quality bleaching rollers that enhance fabric processing.

Clifton Rubber’s bleaching rollers are designed to optimise textile bleaching processes, delivering uniform results, durability, and efficiency. Contact us today to discuss your requirements and find the perfect solution for your production line.