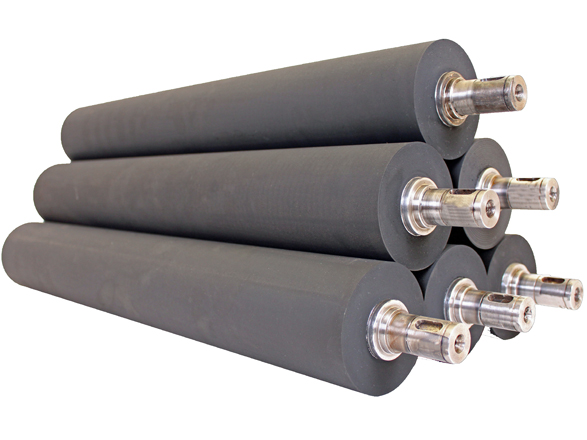

Embossing Rollers for the Paper & Packaging Industry

Embossing rollers are indispensable tools in the paper and packaging industry, enabling manufacturers to achieve high-quality finishes and efficient production. Clifton Rubber specialises in crafting durable, high-performance rollers that meet the specific demands of embossing applications.

Custom Embossing Roller Manufacturer & Supplier for the Paper & Packaging Industry

Our expertise ensures that every roller delivers superior precision, reliability, and longevity, making us a trusted partner for businesses worldwide.

What Are Embossing Rollers?

Embossing rollers are specialised components used in machinery for applying coatings, adhesives, or films onto paper and packaging materials. These rollers ensure an even distribution of substances, providing consistent and flawless finishes.

Features of Clifton Rubber’s Embossing Rollers:

- Precision Engineering: Designed for uniform application across various surfaces.

- Durable Materials: Resistant to wear, abrasion, and chemicals.

- Customisable Options: Tailored sizes, hardness levels, and coatings to suit your needs.

- Reliable Performance: Built to withstand high-speed and high-pressure operations.

The Role of Embossing Rollers in the Industry

Embossing rollers play a vital role in creating durable and visually appealing products. Their applications include:

1. Applying Coatings and Adhesives

These rollers ensure a uniform application of adhesives or coatings, essential for bonding materials or enhancing surface properties.

2. Laminating Films

They facilitate the precise layering of protective films or decorative laminates onto substrates, ensuring a smooth finish.

3. Enhancing Product Quality

By maintaining consistency and accuracy, these rollers help achieve premium-quality end products.

4. Reducing Waste

Efficient embossing processes minimise material waste, improving overall productivity and cost-efficiency.

What Solutions Do Embossing Rollers Provide?

Clifton Rubber’s rollers are engineered to address the challenges faced in embossing processes, offering:

1. Enhanced Durability

Manufactured from robust materials, our rollers resist wear and extend operational lifespan, even in demanding conditions.

2. Optimal Performance

Precision design ensures smooth and consistent application, reducing production errors and downtime.

3. Custom Configurations

We offer tailored solutions with options for rubber, polyurethane, or specialty coatings to meet unique operational requirements.

4. Versatility

Our rollers are compatible with a wide range of coatings, adhesives, and films, making them suitable for diverse applications.

5. Reduced Maintenance Costs

Easy-to-clean and long-lasting, our rollers minimise maintenance efforts, saving time and resources.

About Clifton Rubber

For over 50 years, Clifton Rubber has been a leading manufacturer of embossing rollers for the paper and packaging industry. Our commitment to innovation and quality ensures that our products consistently exceed customer expectations.

Why Choose Clifton Rubber?

- Industry Expertise: Decades of experience in delivering tailored solutions for embossing applications.

- High-Quality Materials: We use premium-grade rubber and polymers to craft durable, reliable rollers.

- Custom Solutions: Our team works closely with you to design rollers that fit your specific machinery and processes.

- Global Reach: Trusted by businesses worldwide for exceptional performance and customer service.

From design to delivery, Clifton Rubber ensures every roller is engineered to optimise your production processes and deliver outstanding results.

Achieve precision, efficiency, and reliability with Clifton Rubber’s embossing rollers. Let us help you elevate your paper and packaging operations to the next level.