Bespoke Rubber Water Valve Lining Project Successfully Delivered to an Engineering Solutions Customer

A bespoke product request is always a welcome and interesting project to undertake. This time our customer was looking for us to manufacture a complex 3-Way Rubber Water Valve Lining and we were happy to take on the challenge.

We were pleased to be approached by a longstanding Global Engineering Solutions customer. They were looking for us to manufacture a complex 3-Way Rubber Water Valve Lining. The customer required these valves in both left-hand and right-hand orientation.

Our Engineering and Production Team are always excited to embark on a Bespoke Project. The challenge and satisfaction of producing something from concept, through design and production to finished product for a happy customer is something few wouldn’t enjoy.

Sample Part to Tooling Design

To start off the project our customer provided us with a sample part from which our experienced draughtsman created a product drawing and tooling design.

Once the mould tool was manufactured, off-tool samples were made and sent for customer approval. The customer gave some feedback as to some of the dimensional requirements of the part and some minor mould amendments were then made at this initial stage.

Further samples were manufactured and signed off by our customer and full production could then get underway. Clifton Rubber Sales Executive, Tom Smith commented: “This has been one of our most interesting and challenging bespoke projects to work on. We were delighted to deliver a successful solution that met our customer’s requirements.”

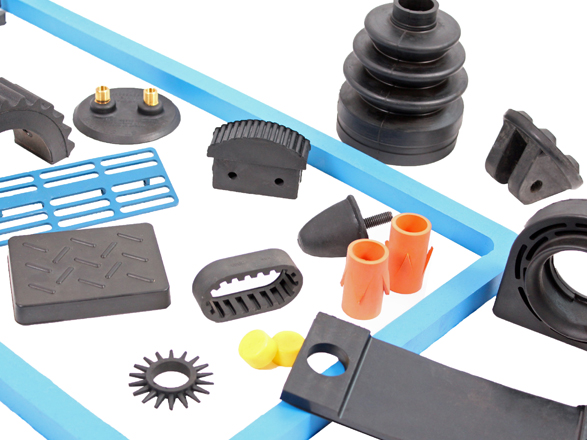

Clifton Rubber incorporates several production units each operating a dedicated rubber or polyurethane processing system.

Our diverse range of material processing resources and technical knowledge ensures no matter how challenging or simple our customer’s requirement, we are best placed to manufacture a high-quality solution.

We have in house engineering facilities and all our tooling is manufactured on site.