Next month we are delighted to again be exhibiting at Potato Europe, which this year is being held in Kain, near Tournai in Belgium on September 6th and 7th, 2023.

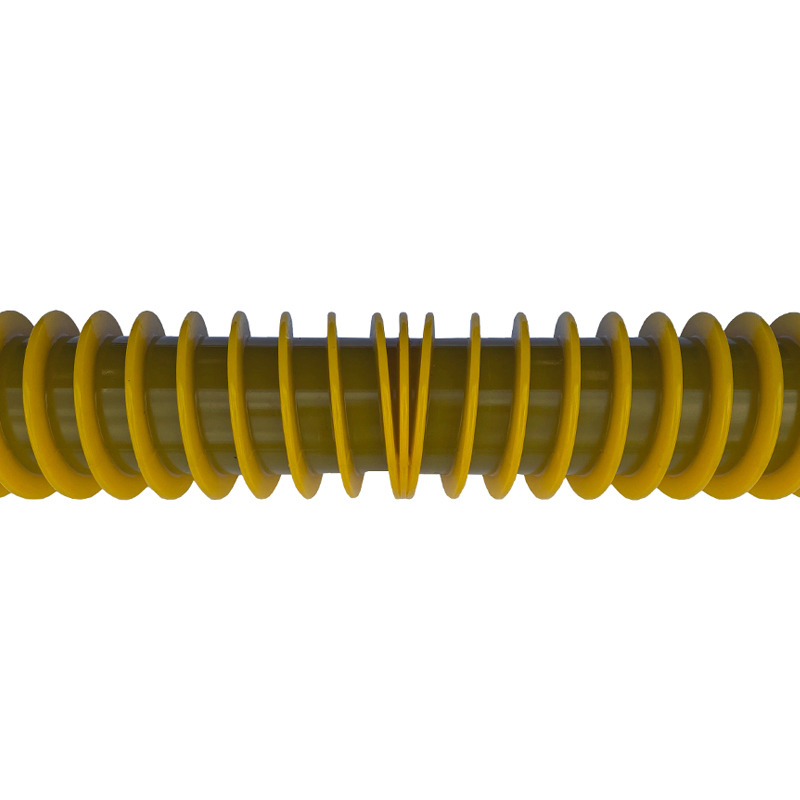

The show is the leading meeting place for those in the Potato Industry, with an exhibition and demonstration area covering over 30 hectares of arable land. At Clifton Rubber we see it as key event in our event calendar and have taken a stand for many years to showcase our range of rubber and polyurethane components.

PotatoEurope 2023, has over 200 different exhibitors from 16 countries showcasing the latest technological developments, a wide range of varieties, and their extensive know-how in all aspects of potato cultivation and processing.

We will be on Stand T87, where we will be delighted to tell you more about our range of rubber and polyurethane products, ideal for use in the agricultural industry.

To find out more about the show click HERE.

Related Articles

- Exhibiting at CEREALS 2024We are delighted to be exhibiting at the CEREALS Show in June.

- Wishing Hemingfords United FC Good Luck in the Cup FinalWe wish good luck this week to Hemingfords United Football Club’s First Team, who will be playing Eynesbury United First in the Intermediate Cup Final 2023-24.

- With Spring just around the corner, have you got protection in place for your Bowling Green Ditches?Want to make sure your green is in great playing condition as your Club re-opens in the Spring?